- 0086-571-85302990

- sales@greenskybio.com

Only cooperate with the best contract manufacturers of quercetin.

2024-12-10

1. Introduction

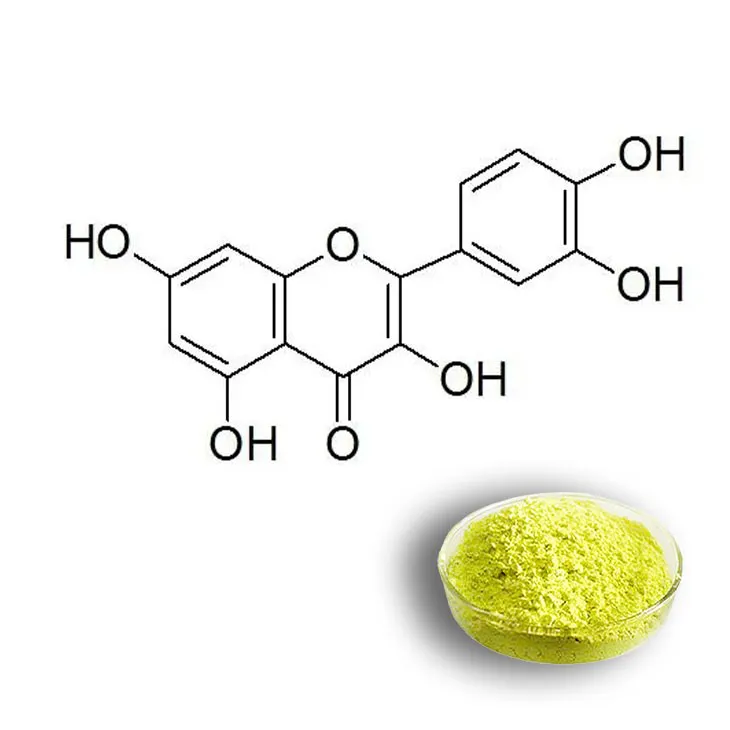

Quercetin, a flavonoid with numerous potential health benefits, has been gaining increasing attention in various industries, including the pharmaceutical, nutraceutical, and food supplement sectors. Its production is a complex process that demands a high - level of precision and quality control. In this regard, cooperating with the best contract manufacturers is not just an option but a necessity for businesses involved in Quercetin production. This article delves into the reasons behind this and analyzes how the top contract manufacturers can ensure product purity, consistency, and safety in Quercetin manufacturing.

2. The Importance of Quercetin

Quercetin has been studied for its antioxidant, anti - inflammatory, and potential anti - cancer properties. It is found in various fruits, vegetables, and herbs, but for commercial and therapeutic applications, a concentrated and purified form is often required.

2.1 Antioxidant Activity

As an antioxidant, quercetin helps to neutralize free radicals in the body. Free radicals are unstable molecules that can cause damage to cells and are associated with various diseases, including heart disease, cancer, and neurodegenerative disorders. Quercetin's antioxidant ability makes it a valuable component in products aimed at promoting overall health and preventing chronic diseases.

2.2 Anti - Inflammatory Effects

It has also been shown to have anti - inflammatory properties. Inflammation is a natural response of the body to injury or infection, but chronic inflammation can be harmful. Quercetin can modulate the body's inflammatory response by inhibiting certain enzymes and signaling pathways involved in inflammation. This makes it potentially useful in the treatment of inflammatory conditions such as arthritis.

3. Challenges in Quercetin Manufacturing

Manufacturing quercetin is not without its challenges. The process requires careful extraction, purification, and formulation to ensure the final product meets the required quality standards.

3.1 Raw Material Variability

The starting materials for quercetin production, such as plant sources, can vary in their quercetin content. Different varieties of plants, growing conditions, and harvesting times can all affect the amount and quality of quercetin available for extraction. This variability in raw materials can pose a challenge in achieving consistent product quality.

3.2 Extraction and Purification Processes

The extraction of quercetin from plant sources is a complex process. Different extraction methods, such as solvent extraction, supercritical fluid extraction, or enzymatic extraction, have their own advantages and disadvantages. After extraction, the purification process is crucial to remove impurities and obtain a high - purity quercetin product. Any errors or inefficiencies in these processes can lead to a product with lower purity or inconsistent quality.

3.3 Formulation and Stability

Once purified, quercetin needs to be formulated into a suitable product form, such as tablets, capsules, or powders. During this process, factors such as solubility, stability, and bioavailability need to be considered. Quercetin can be sensitive to environmental factors such as light, heat, and moisture, which can affect its stability. Ensuring the long - term stability of the formulated product is essential for its effectiveness and shelf - life.

4. Advantages of the Best Contract Manufacturers

The best contract manufacturers bring a host of advantages to quercetin production.

4.1 Expertise in Extraction and Purification

Top contract manufacturers have extensive experience and expertise in the extraction and purification of quercetin. They are well - versed in different extraction methods and can select the most appropriate one based on the raw materials and desired product quality. For example, they may choose supercritical fluid extraction for its ability to produce a high - purity product with minimal solvent residue in some cases. Their purification processes are also highly advanced, using techniques such as chromatography to remove impurities effectively. This ensures that the final quercetin product has a high level of purity.

4.2 Quality Control and Assurance

These manufacturers have strict quality control systems in place. They conduct regular tests at every stage of the manufacturing process, from raw material inspection to final product analysis. This includes testing for purity, identity, and potency of quercetin. By implementing comprehensive quality control measures, they can ensure that the product is consistent in quality from batch to batch. For instance, they may use high - performance liquid chromatography (HPLC) to accurately measure the quercetin content and detect any impurities.

4.3 Research and Development Capabilities

The best contract manufacturers often invest in research and development. They are constantly looking for ways to improve the manufacturing process, enhance product quality, and develop new formulations of quercetin. This could involve exploring new extraction techniques, finding ways to increase the bioavailability of quercetin, or developing innovative product forms. Their R & D efforts can lead to a competitive edge for the businesses they collaborate with, as they can offer unique and improved quercetin products in the market.

4.4 Compliance with Regulations

Quercetin products are subject to various regulations, depending on their intended use. Whether it is for use in dietary supplements or pharmaceuticals, manufacturers need to comply with relevant safety and quality standards. The top contract manufacturers are well - aware of these regulations and ensure that their manufacturing processes and products meet all the necessary requirements. This includes following good manufacturing practices (GMP) and obtaining the required certifications. By partnering with compliant contract manufacturers, businesses can avoid potential legal issues and ensure the safety and legality of their quercetin products.

5. Ensuring Product Purity

Product purity is of utmost importance in quercetin manufacturing. The best contract manufacturers employ several strategies to achieve high - purity quercetin products.

5.1 Selecting High - Quality Raw Materials

They start by carefully selecting the raw materials. This involves sourcing from reliable suppliers and choosing plant varieties known for their high quercetin content. They may also conduct pre - extraction tests on the raw materials to ensure their suitability for the manufacturing process. By starting with high - quality raw materials, they can lay a solid foundation for producing a pure quercetin product.

5.2 Advanced Extraction and Purification Techniques

As mentioned earlier, these manufacturers use advanced extraction and purification techniques. For extraction, they may optimize the parameters of the chosen method to maximize the yield of quercetin while minimizing the extraction of unwanted substances. In the purification stage, they use state - of - the - art chromatography techniques, such as reverse - phase HPLC, to separate quercetin from impurities with high precision. These techniques help to ensure that the final product contains a high percentage of pure quercetin.

5.3 Stringent Quality Testing

Throughout the manufacturing process, strict quality testing is carried out. This includes testing for the presence of impurities, such as heavy metals, pesticides, and other flavonoids. Any product that does not meet the purity standards is rejected. By maintaining a high level of quality testing, the contract manufacturers can guarantee the purity of the quercetin products they produce.

6. Ensuring Product Consistency

Consistency in product quality is crucial for businesses dealing with quercetin. The best contract manufacturers take steps to ensure that each batch of quercetin they produce is consistent.

6.1 Standardized Manufacturing Processes

They have standardized manufacturing processes in place. This means that each step of the extraction, purification, and formulation processes is clearly defined and followed precisely. By using standardized procedures, they can minimize variations in the final product. For example, the temperature, pressure, and reaction times in the extraction process are carefully controlled to ensure consistent results.

6.2 Batch - to - Batch Quality Monitoring

Regular batch - to - batch quality monitoring is an essential part of their operations. They compare the quality parameters of each new batch with previous batches and with the established quality standards. If any deviations are detected, they take corrective actions immediately. This continuous monitoring helps to maintain consistency in product quality over time.

6.3 Documentation and Traceability

Good documentation and traceability are also key aspects of ensuring product consistency. The contract manufacturers keep detailed records of every aspect of the manufacturing process, from raw material sourcing to final product distribution. This allows them to trace any issues back to their source and make necessary adjustments. It also provides transparency to their clients, who can be assured of the consistency of the products they are receiving.

7. Ensuring Product Safety

Safety is a non - negotiable aspect of quercetin manufacturing. The best contract manufacturers implement various measures to ensure the safety of their quercetin products.

7.1 Raw Material Safety

They ensure the safety of the raw materials used in quercetin production. This includes screening for contaminants such as pesticides, heavy metals, and mycotoxins. Only raw materials that pass strict safety tests are used in the manufacturing process. This helps to prevent the introduction of harmful substances into the final product.

7.2 Manufacturing Environment and Hygiene

The manufacturing environment is maintained in a clean and hygienic state. The facilities are designed to meet strict hygiene standards, with proper ventilation, temperature control, and sanitation procedures. This helps to prevent the growth of microorganisms and the contamination of the product during the manufacturing process.

7.3 Final Product Safety Testing

Before the quercetin product is released, it undergoes comprehensive safety testing. This includes testing for toxicity, allergenicity, and microbiological safety. Only products that pass all these safety tests are considered fit for distribution. By conducting these final product safety tests, the contract manufacturers can ensure that the quercetin products they produce are safe for consumers.

8. Benefits for Businesses

Cooperating with the best contract manufacturers of quercetin offers several benefits for businesses involved in the production and marketing of quercetin - based products.

8.1 Cost - Efficiency

By outsourcing the manufacturing to expert contract manufacturers, businesses can save on the costs associated with building and maintaining their own manufacturing facilities. The contract manufacturers can take advantage of economies of scale, which can result in lower production costs. This cost - efficiency can translate into higher profit margins for the businesses.

8.2 Focus on Core Competencies

Businesses can focus on their core competencies, such as marketing, product development, and customer service, while leaving the manufacturing process to the experts. This allows them to allocate their resources more effectively and improve their overall competitiveness in the market.

8.3 Access to Advanced Technology and Expertise

Partnering with top contract manufacturers gives businesses access to the latest manufacturing technology and expertise. This can enable them to produce high - quality quercetin products that are competitive in the market. It also provides them with opportunities for innovation and product differentiation.

8.4 Risk Mitigation

The best contract manufacturers have a proven track record in compliance and quality control. By partnering with them, businesses can mitigate the risks associated with non - compliance, product recalls, and quality issues. This helps to protect the reputation and financial stability of the businesses.

9. Conclusion

In conclusion, quercetin manufacturing is a complex and challenging process that requires a high level of precision and quality control. Cooperating with the best contract manufacturers is the key to ensuring product purity, consistency, and safety. The top contract manufacturers bring expertise, quality control, research and development capabilities, and compliance with regulations to the table. For businesses involved in quercetin, this optimal cooperation offers numerous benefits, including cost - efficiency, the ability to focus on core competencies, access to advanced technology, and risk mitigation. As the demand for quercetin - based products continues to grow, partnering with the best contract manufacturers will be crucial for success in this competitive market.

FAQ:

Q1: What are the key factors to consider when choosing the best contract manufacturers for quercetin?

When choosing the best contract manufacturers for quercetin, several key factors should be considered. Firstly, their manufacturing experience in the field of quercetin production is crucial. Manufacturers with a long - standing history in this area are more likely to have mastered the precise production techniques. Secondly, quality control measures are of great importance. This includes strict inspection of raw materials, in - process quality checks, and final product verification to ensure product purity, consistency, and safety. Thirdly, compliance with relevant regulations and industry standards. Manufacturers need to follow strict regulatory requirements such as Good Manufacturing Practice (GMP). Fourthly, technological capabilities. Advanced production equipment and innovative technologies can contribute to more efficient and high - quality production of quercetin. Finally, reputation and customer reviews. A good reputation in the industry and positive customer feedback can be an indicator of reliable manufacturing services.

Q2: How do the best contract manufacturers ensure the purity of quercetin?

The best contract manufacturers ensure the purity of quercetin through multiple methods. They start with strict sourcing of raw materials. Only high - quality raw materials are selected, and these are thoroughly tested for purity before use. During the manufacturing process, advanced purification techniques are employed. This may include chromatography methods which can effectively separate quercetin from other substances. Stringent quality control at each stage of production also helps. Regular sampling and analysis are carried out to detect and remove any impurities. Additionally, proper storage and handling conditions are maintained to prevent contamination that could affect purity.

Q3: What role does consistency play in quercetin manufacturing by contract manufacturers?

Consistency is highly important in quercetin manufacturing by contract manufacturers. It ensures that each batch of quercetin produced has the same quality characteristics. This is crucial for businesses relying on quercetin for their products. For example, in the pharmaceutical or nutraceutical industries, consistent product quality is necessary for accurate dosing and reliable therapeutic or health - promoting effects. Contract manufacturers achieve consistency through standardized production processes. They use precise manufacturing protocols, calibrated equipment, and well - trained staff. Regular calibration and maintenance of equipment also contribute to consistent production. Moreover, quality control checks at various stages of production help to identify and correct any variations that could affect consistency.

Q4: How do top contract manufacturers ensure the safety of quercetin products?

Top contract manufacturers ensure the safety of quercetin products in several ways. Firstly, they adhere to strict safety regulations and industry standards. This includes following guidelines for handling, processing, and storing quercetin. For example, compliance with Occupational Safety and Health Administration (OSHA) regulations in the workplace. Secondly, they conduct thorough risk assessments during the manufacturing process. This helps to identify potential hazards such as chemical reactions or exposure risks and take appropriate preventive measures. Thirdly, strict quality control on raw materials and final products. Testing for contaminants, heavy metals, and other harmful substances is carried out. Fourthly, proper packaging is used to protect the quercetin from environmental factors that could affect its safety during storage and transportation.

Q5: What are the benefits for businesses to cooperate with the best contract manufacturers of quercetin?

Businesses can gain several benefits from cooperating with the best contract manufacturers of quercetin. Firstly, they can ensure high - quality products. The manufacturers' expertise in ensuring purity, consistency, and safety of quercetin can enhance the overall quality of the businesses' end - products. Secondly, cost - effectiveness. Instead of investing in their own manufacturing facilities and R & D for quercetin production, businesses can save costs by outsourcing to contract manufacturers. Thirdly, access to advanced technology and innovation. The best contract manufacturers are often equipped with the latest production technologies, which businesses can leverage. Fourthly, reduced time - to - market. Contract manufacturers with their established production processes can speed up the production cycle, allowing businesses to get their quercetin - related products to the market faster. Finally, regulatory compliance support. The manufacturers' knowledge and compliance with regulations can help businesses avoid legal issues related to quercetin production.

Related literature

- Quercetin Production: Meeting the Highest Quality Standards"

- "The Role of Contract Manufacturers in Ensuring Quercetin Purity"

- "Advances in Quercetin Manufacturing by Top - tier Contract Manufacturers"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

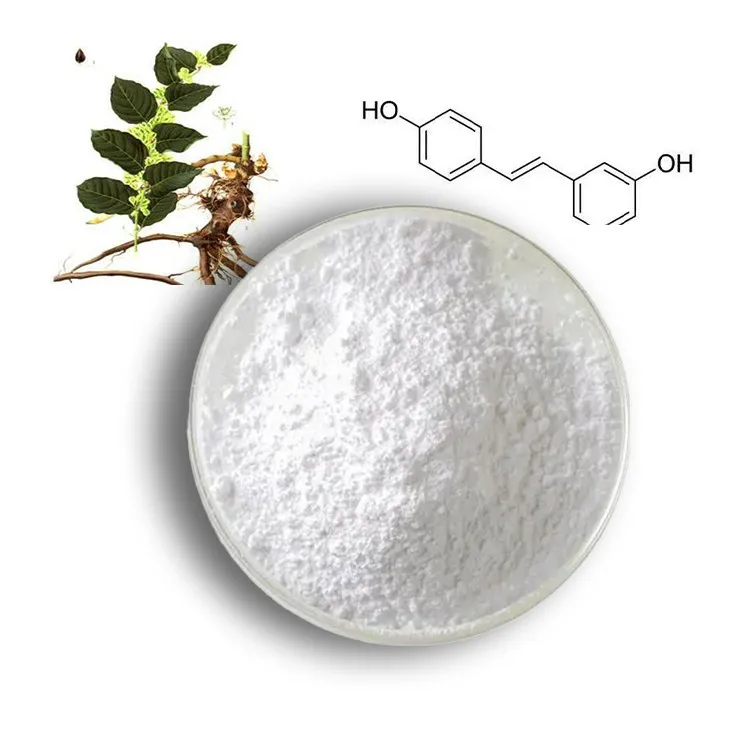

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Wheat Germ Extract

2024-12-10

-

Red Vine Extract

2024-12-10

-

Golden Seal Extract

2024-12-10

-

Resveratrol extract

2024-12-10

-

Alfalfa Meal

2024-12-10

-

Garcinia Cambogia Extract

2024-12-10

-

Genistein

2024-12-10

-

Black Rice Extract

2024-12-10

-

Konjac Powder

2024-12-10

-

Fig Extract

2024-12-10