- 0086-571-85302990

- sales@greenskybio.com

Understand the main processes of purple sweet potato extract manufacturing in the food industry.

2024-12-11

1. Introduction

In the modern food industry, the demand for natural and healthy ingredients is constantly increasing. Purple Sweet Potato Extract has emerged as a popular choice due to its rich nutritional value and diverse applications. This article aims to comprehensively explain the main processes involved in the manufacturing of Purple Sweet Potato Extract.

2. Raw Material Selection

The first and crucial step in the manufacturing process is raw material selection.

2.1 Quality Criteria

High - quality purple sweet potatoes need to be carefully chosen. They should be fresh, which is essential for ensuring the quality of the final extract. Any signs of spoilage or decay can negatively impact the taste, nutritional value, and overall quality of the extract. Moreover, the purple sweet potatoes must be free from diseases or contaminants. Diseases can affect the chemical composition of the sweet potatoes, and contaminants such as pesticides or heavy metals can pose serious health risks if present in the extract.

2.2 Sourcing Considerations

When sourcing purple sweet potatoes, producers often consider factors such as the origin of the sweet potatoes. Sweet potatoes grown in certain regions may have different characteristics in terms of taste, nutrient content, and suitability for extraction. Additionally, sustainable farming practices are also becoming an important consideration. Purple sweet potatoes sourced from farms that follow environmentally - friendly and sustainable farming methods are generally preferred as they are more likely to be free from harmful chemicals and support long - term environmental health.

3. Cleaning Process

Once the purple sweet potatoes are selected, the next step is the cleaning process.

3.1 Importance of Thorough Cleaning

The purple sweet potatoes are thoroughly washed to remove dirt, sand and other impurities. Dirt and sand can not only affect the purity of the extract but also cause damage to the extraction equipment. If these impurities are not removed completely, they may clog the filters or other components during the extraction and purification processes, leading to inefficiencies and potential breakdowns of the equipment.

3.2 Cleaning Methods

There are various methods for cleaning purple sweet potatoes. One common method is to use running water. The sweet potatoes are placed under a stream of running water, and gentle scrubbing may be applied to ensure that all the dirt and debris are removed. Another method is to soak the sweet potatoes in water for a certain period of time, which can help loosen the dirt and make it easier to wash off. However, the soaking time needs to be carefully controlled to avoid excessive water absorption by the sweet potatoes, which could potentially affect the extraction process later.

4. Peeling

After cleaning, the purple sweet potatoes are then peeled to get rid of the outer skin.

4.1 Reasons for Peeling

The outer skin of purple sweet potatoes may contain unwanted substances. For example, it may have pesticides residues if not properly washed, or it may contain tough fibers that are not suitable for extraction. Peeling ensures that the extract is obtained from the pure flesh of the sweet potatoes, which contains the desired nutrients and bioactive compounds.

4.2 Peeling Techniques

There are manual and mechanical peeling methods. Manual peeling is suitable for small - scale production or when a high level of precision is required. However, it is time - consuming and labor - intensive. Mechanical peeling, on the other hand, is more efficient for large - scale production. There are different types of mechanical peelers available, such as rotary peelers and abrasion peelers. Rotary peelers use rotating blades to cut away the skin, while abrasion peelers remove the skin by rubbing the surface of the sweet potatoes.

5. Extraction Step

The peeled purple sweet potatoes are then subjected to the extraction step, which is a key part of the manufacturing process.

5.1 Preparation of Purple Sweet Potatoes for Extraction

Before extraction, the peeled purple sweet potatoes are usually crushed or mashed into a pulp. This increases the surface area of the sweet potatoes, allowing for more efficient extraction of the beneficial components. The degree of crushing or mashing can vary depending on the extraction method and the desired characteristics of the extract. For example, a finer pulp may be required for certain extraction techniques to ensure maximum extraction yield.

5.2 Choice of Solvents

Appropriate solvents are used to extract the beneficial components from the purple sweet potato pulp. Commonly used solvents include water and ethanol. Water is a natural and safe solvent, and it is often preferred when the goal is to extract water - soluble nutrients such as sugars, some vitamins, and minerals. Ethanol, on the other hand, is a better solvent for extracting lipophilic compounds such as certain pigments and antioxidants. The choice of solvent depends on the specific components that are targeted for extraction in the Purple Sweet Potato Extract.

5.3 Extraction Conditions

This extraction process may be carried out under specific temperature and pressure conditions to optimize the yield. Temperature can significantly affect the solubility of the components in the solvent and the rate of extraction. Higher temperatures may generally increase the solubility and extraction rate, but excessive heat can also cause degradation of some heat - sensitive components. Similarly, pressure can also influence the extraction process. Controlled pressure can help to drive the solvent into the purple sweet potato pulp and enhance the extraction efficiency. However, inappropriate pressure can lead to equipment failure or incomplete extraction.

6. Purification

After the extraction, the resulting extract needs to be purified.

6.1 Importance of Purification

The purification process is necessary to remove any remaining impurities such as insoluble particles or excess solvent. Insoluble particles can affect the clarity and stability of the extract, while excess solvent can change the concentration and composition of the extract. A purified extract is of higher quality and more suitable for various applications in the food industry.

6.2 Purification Techniques

Filtration is a common purification technique. There are different types of filters that can be used, such as paper filters, membrane filters, and filter presses. Paper filters are suitable for removing larger particles, while membrane filters with smaller pore sizes can be used to remove finer particles and even some microorganisms. Filter presses are often used for large - scale production to achieve efficient filtration. In addition to filtration, other techniques such as centrifugation can also be used to separate the extract from impurities. Centrifugation uses the principle of centrifugal force to separate substances of different densities, allowing for the removal of heavier impurities from the extract.

7. Concentration and Final Processing

The final steps in the manufacturing of purple sweet potato extract are concentration and further processing.

7.1 Concentration

The purified purple sweet potato extract is concentrated to increase the concentration of the active components. This can be achieved through methods such as evaporation. Evaporation removes the solvent, leaving behind a more concentrated extract. The degree of concentration depends on the intended use of the extract. For example, a higher concentration may be required for use as a nutritional supplement, while a lower concentration may be suitable for use as a natural colorant.

7.2 Final Processing Forms

The concentrated purple sweet potato extract may be further processed into different forms such as powder or liquid for use in the food industry. Powder form is often preferred for its ease of storage, transportation, and long - shelf life. It can be easily incorporated into various food products such as baked goods, beverages, and confectionery. Liquid form, on the other hand, is more convenient for direct use in some food processing operations, such as adding to sauces or dressings. The choice of the final form depends on the specific requirements of the food manufacturers and the end - use applications of the purple sweet potato extract.

8. Conclusion

The manufacturing process of purple sweet potato extract in the food industry involves multiple important steps, from raw material selection to final processing. Each step plays a crucial role in ensuring the quality, purity, and usability of the extract. As the demand for natural and healthy food ingredients continues to grow, understanding these manufacturing processes is essential for both producers and consumers in the food industry.

FAQ:

What are the criteria for selecting raw purple sweet potatoes in the manufacturing process?

High - quality purple sweet potatoes should be carefully chosen. They need to be fresh and free from diseases or contaminants.

Why is the cleaning process necessary for purple sweet potatoes before extraction?

The cleaning process is necessary to remove dirt, sand and other impurities from the purple sweet potatoes.

What are the common solvents used in the extraction step of purple sweet potato extract?

Water or ethanol are common solvents used in the extraction step.

How is the purple sweet potato extract purified?

The purple sweet potato extract is purified through filtration and other techniques to remove any remaining impurities such as insoluble particles or excess solvent.

What are the final forms of purple sweet potato extract for use in the food industry?

The purified purple sweet potato extract can be concentrated and further processed into different forms such as powder or liquid for use in the food industry, for example, as a natural colorant or a nutritional supplement.

Related literature

- Purple Sweet Potato Extract: Production and Applications in the Food Industry"

- "Manufacturing Processes of Functional Extracts from Purple Sweet Potatoes"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

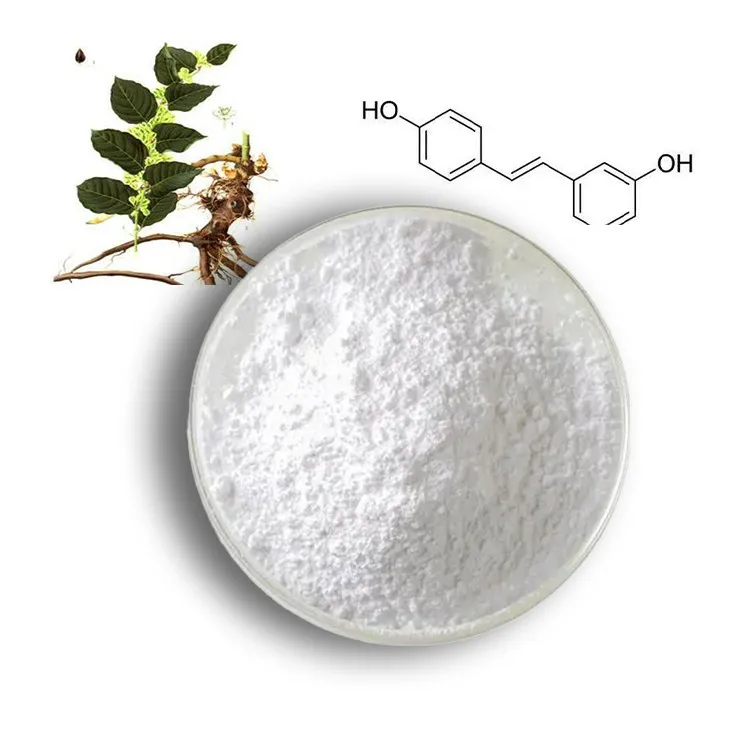

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Alfalfa Meal

2024-12-11

-

Reishi mushroom extract

2024-12-11

-

Lavender Extract

2024-12-11

-

Oyster Mushroom Extract Powder

2024-12-11

-

Agaricus Blazei Extract

2024-12-11

-

Resveratrol extract

2024-12-11

-

Konjac Powder

2024-12-11

-

Alisma Extract

2024-12-11

-

Green coffee bean Extract

2024-12-11

-

Red Vine Extract

2024-12-11