- 0086-571-85302990

- sales@greenskybio.com

Only cooperate with the best contract manufacturers of bamboo leaf extracts.

2024-12-10

Introduction

Bamboo Leaf extract has been increasingly recognized for its various potential applications in the fields of health, food, and cosmetics. As the demand for Bamboo Leaf extract rises, the importance of choosing the right contract manufacturer cannot be overstated. A reliable and high - quality contract manufacturer can ensure the purity, effectiveness, and safety of the Bamboo Leaf extract products, which is crucial for businesses aiming to succeed in this growing market.

Expertise in Bamboo Leaf Extract Processing

1. Botanical Knowledge

The best contract manufacturers should have in - depth knowledge of bamboo as a plant. They need to understand the different species of bamboo that are suitable for extraction, their growth conditions, and the variations in chemical composition among different bamboo sources. For example, some species of bamboo may contain higher levels of bioactive compounds such as flavonoids, which are highly valued in the health and wellness industry. Manufacturers with botanical expertise can select the most appropriate bamboo sources, ensuring the quality of the extract from the very beginning.

2. Extraction Techniques

There are various extraction methods for bamboo leaf extract, including solvent extraction, supercritical fluid extraction, and microwave - assisted extraction. Each method has its own advantages and disadvantages in terms of extraction efficiency, selectivity, and the preservation of bioactive compounds.

- Solvent Extraction: This is a traditional method. A good contract manufacturer should be proficient in choosing the right solvents (such as ethanol, water - ethanol mixtures) and optimizing extraction parameters like temperature, time, and solvent - to - material ratio. For example, using a too - high temperature during solvent extraction may lead to the degradation of some heat - sensitive bioactive compounds. - Supercritical Fluid Extraction: It offers the advantage of producing a cleaner extract with less solvent residue. Manufacturers need to have the technology and expertise to operate supercritical fluid extraction equipment, such as controlling the pressure and temperature of the supercritical CO2 to achieve optimal extraction results. - Microwave - Assisted Extraction: This method can significantly reduce extraction time. However, it requires precise control of microwave power and irradiation time to avoid over - extraction or damage to the bioactive components.

3. Product Formulation

Once the bamboo leaf extract is obtained, the contract manufacturer should be able to formulate it into various products. For the health supplement market, they need to know how to blend the extract with other ingredients in a way that is both effective and compliant with regulatory requirements. In the food industry, they should be able to incorporate the extract into different food matrices without affecting the taste, texture, and shelf - life of the products. For cosmetics, they must understand how to formulate the extract into creams, lotions, and other products to enhance skin - related benefits.

Advanced Technology and Equipment

1. Quality Control Equipment

High - quality contract manufacturers invest in state - of - - art quality control equipment. For example, they use high - performance liquid chromatography (HPLC) to analyze the chemical composition of the bamboo leaf extract accurately. HPLC can separate and quantify the different bioactive compounds in the extract, allowing manufacturers to ensure that the product meets the specified standards. Gas chromatography - mass spectrometry (GC - MS) is also useful for detecting volatile components and contaminants in the extract.

2. Production Equipment

Modern production equipment is essential for efficient and large - scale production of bamboo leaf extract. For solvent extraction, the equipment should be designed to ensure uniform mixing of the solvent and bamboo leaves, and efficient separation of the extract. In supercritical fluid extraction, the equipment needs to be able to maintain stable pressure and temperature conditions. Moreover, automated production lines can improve production efficiency, reduce human error, and ensure product consistency.

Compliance with Industry Standards

1. Regulatory Requirements

Depending on the intended use of the bamboo leaf extract (e.g., as a dietary supplement, food ingredient, or cosmetic ingredient), different regulatory requirements apply. In the United States, for example, dietary supplements are regulated under the Dietary Supplement Health and Education Act (DSHEA). Manufacturers need to ensure that their production processes and products comply with these regulations, including proper labeling, ingredient safety, and manufacturing practices.

- Labeling: The label should clearly state the content of bamboo leaf extract, its source, and any potential allergens. For example, if the extract is used in a food product, it must comply with the Food Allergen Labeling and Consumer Protection Act (FALCPA) in the US. - Ingredient Safety: The contract manufacturer is responsible for ensuring that the bamboo leaf extract is free from harmful contaminants such as heavy metals (e.g., lead, mercury), pesticides, and microbial contaminants. They need to conduct regular tests to meet safety standards. - Manufacturing Practices: Good Manufacturing Practice (GMP) regulations govern the production environment, equipment maintenance, and personnel training. Manufacturers must follow GMP to ensure the quality and safety of the product.

2. Quality Standards

There are also international and industry - specific quality standards for bamboo leaf extract. For instance, the International Organization for Standardization (ISO) may have relevant standards for the extraction process, product purity, and quality control. Manufacturers should strive to meet these standards to ensure the competitiveness of their products in the global market.

Conclusion

When it comes to bamboo leaf extract, choosing the best contract manufacturer is a multi - faceted decision. Their expertise in bamboo leaf extract processing, advanced technology and equipment, and compliance with industry standards all play crucial roles. By carefully evaluating these factors, businesses can find a contract manufacturer that can produce high - quality bamboo leaf extract products, which will help them succeed in the growing market related to this valuable natural extract.

FAQ:

What are the main criteria for a contract manufacturer to be considered the best for bamboo leaf extract?

The main criteria include having in - depth expertise in handling bamboo leaf extract, advanced extraction technology, strict compliance with industry quality and safety standards, a reliable supply chain, and a good reputation in the market.

How can one assess the expertise of a contract manufacturer in bamboo leaf extract?

One can assess their expertise by looking at their experience in the field, the qualifications of their staff, research and development efforts related to bamboo leaf extract, and their understanding of the properties and applications of the extract.

Why is technology important in a contract manufacturer for bamboo leaf extract?

Advanced technology is crucial as it can ensure efficient extraction, high - quality purification, accurate quality control, and the ability to meet different production requirements. It can also contribute to innovation in product development.

What industry standards should a good contract manufacturer of bamboo leaf extract comply with?

They should comply with quality standards such as GMP (Good Manufacturing Practice), safety standards for food or pharmaceutical applications (if relevant), and environmental protection regulations. They may also need to follow international standards for trade and quality control.

How does the choice of contract manufacturer affect the quality of bamboo leaf extract products?

The choice of contract manufacturer has a significant impact on product quality. A good manufacturer will use proper raw materials, advanced extraction and processing techniques, strict quality control, and ensure proper packaging and storage, all of which contribute to high - quality bamboo leaf extract products.

Related literature

- Bamboo Leaf Extract: Properties and Applications"

- "Quality Control in Bamboo Leaf Extract Production"

- "The Role of Technology in Extracting Bamboo Leaf Extract"

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Problems

- ▶ Boswellia Serrata Extract

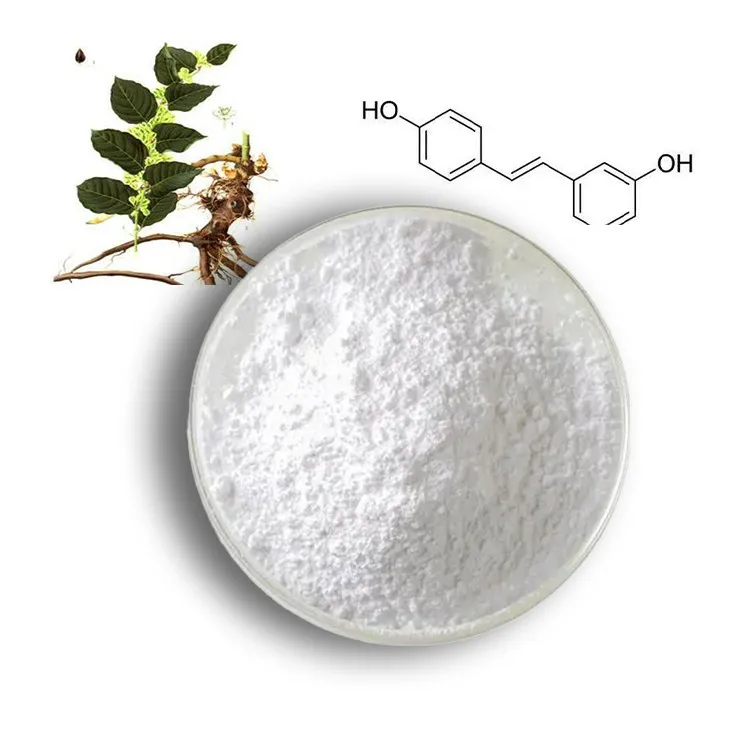

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

-

Phellodendron Extract

2024-12-10

-

Andrographis Paniculata Extract Powder

2024-12-10

-

Dandelion Root Extract

2024-12-10

-

Peppermint Extract Powder

2024-12-10

-

Phyllanthus Emblica Extract

2024-12-10

-

Sea buckthorn Juice Powder

2024-12-10

-

Golden Seal Extract

2024-12-10

-

Resveratrol extract

2024-12-10

-

Oyster Mushroom Extract Powder

2024-12-10

-

Eucommia Ulmoides Extract

2024-12-10