- 0086-571-85302990

- sales@greenskybio.com

A Guide to Understanding the Powder Proportion of Marigold Extract.

2024-12-10

1. Introduction

Marigold Extract powder has been gaining significant attention in various industries, including food, cosmetics, and pharmaceuticals. The powder proportion of Marigold Extract plays a crucial role in determining its effectiveness and suitability for different applications. Understanding this proportion is essential for manufacturers, researchers, and consumers alike.

2. Significance of Different Ratios in Different Applications

2.1 Food Industry

In the food industry, Marigold Extract powder is often used for its coloring properties. A low ratio of the extract powder may be sufficient for adding a subtle yellow - orange hue to certain products, such as dairy products like cheese or butter. For example, a ratio of 1:100 (extract powder to the total product mass) might be used in a mild - flavored cheese to give it a natural - looking color without overpowering the taste. On the other hand, in products like candies or processed snacks where a more vibrant color is desired, a higher ratio could be employed, perhaps 1:50 or even 1:20. This allows for a more intense and appealing color that can attract consumers.

2.2 Cosmetics Industry

The cosmetics industry utilizes marigold extract powder for its antioxidant and skin - soothing properties. In skin creams and lotions, a relatively low ratio, say 1:200, can be used to provide a gentle antioxidant boost. This is because the skin is a sensitive organ, and a high concentration of the extract might cause irritation in some individuals. However, in products like lip balms where a more concentrated effect is desired, a ratio of 1:50 or 1:100 could be appropriate. The extract can help protect the lips from environmental damage and keep them moisturized.

2.3 Pharmaceutical Industry

For the pharmaceutical industry, marigold extract powder is being studied for its potential medicinal properties. In the development of herbal supplements, the ratio needs to be carefully determined. A very low ratio, such as 1:500, might be used in initial formulations for safety testing. As research progresses and the effectiveness of the extract is better understood, the ratio could be adjusted. For example, in a supplement aimed at treating certain eye conditions related to oxidative stress, a ratio of 1:100 might be considered, as it can provide a sufficient amount of the active compounds without causing adverse effects.

3. Factors Influencing the Optimal Ratio

3.1 Source of Marigold

The type and quality of the marigold plant used for extraction can greatly influence the optimal powder proportion. Different varieties of marigolds may have varying levels of active compounds. For instance, the Tagetes erecta variety is known to have a relatively high content of lutein and zeaxanthin. If this variety is used as the source, a lower ratio of the extract powder might be sufficient in applications where these compounds are the main focus, such as in eye - health supplements. On the other hand, if a less potent variety is used, a higher ratio may be required to achieve the same effect.

3.2 Extraction Method

The method used to extract the marigold extract also plays a role in determining the optimal ratio. Solvent - based extraction methods may result in a more concentrated extract, which could mean that a lower ratio of the powder is needed in the final product. However, these methods may also introduce impurities or residual solvents that need to be carefully removed. Supercritical fluid extraction, on the other hand, can produce a purer extract, but the cost is relatively high. Depending on the extraction method, the proportion of the powder in the end - use product may need to be adjusted accordingly.

3.3 Targeted Activity

The specific activity or benefit that the marigold extract powder is intended to provide also affects the ratio. If the goal is to achieve a strong antioxidant effect, a higher ratio of the extract powder may be required, as more of the antioxidant - rich compounds need to be present. In contrast, if the focus is on a mild anti - inflammatory property, a lower ratio might be sufficient. For example, in a product designed to soothe minor skin irritations, a ratio of 1:300 could be enough, while for a product aiming for a more pronounced antioxidant protection, a ratio of 1:100 or even 1:50 may be necessary.

4. How to Determine the Right Proportion for Specific Needs

4.1 Research and Literature Review

One of the first steps in determining the right proportion of marigold extract powder for a specific need is to conduct a thorough research and literature review. There are numerous scientific studies available on the properties and applications of marigold extract. By examining these studies, one can get an idea of the ratios that have been successfully used in similar applications. For example, if developing a new skin - care product, looking at research on marigold extract in existing skin - care formulations can provide valuable insights. This may involve searching through academic databases, industry reports, and patent literature.

4.2 Pilot - scale Testing

After gathering information from the literature, pilot - scale testing is often necessary. This involves creating small - batch samples with different ratios of marigold extract powder and evaluating their performance. In the food industry, this could mean making small batches of a new food product with varying levels of the extract powder and conducting sensory evaluations to determine the best ratio in terms of taste, color, and overall acceptability. In the cosmetics industry, pilot - scale testing might include applying different formulations to a small group of volunteers to assess skin compatibility and the desired effect. Through this process, one can narrow down the range of suitable ratios and identify any potential issues such as instability or unexpected reactions.

4.3 Regulatory Considerations

Another important aspect in determining the right proportion is regulatory considerations. Different industries are subject to various regulations regarding the use of natural extracts in products. In the food industry, there are strict limits on the amount of additives, including marigold extract powder, that can be used. For example, in some countries, there are maximum allowable levels set for color additives derived from marigold extract. In the cosmetics and pharmaceutical industries, regulations also govern the safety and efficacy of products containing the extract. Manufacturers must ensure that the proportion of marigold extract powder used complies with all relevant regulations to avoid legal issues and ensure consumer safety.

5. Conclusion

In conclusion, understanding the powder proportion of marigold extract is a complex but essential task. The ratio can vary significantly depending on the application, the source of the marigold, the extraction method, and the targeted activity. By carefully considering these factors, conducting research, performing pilot - scale testing, and adhering to regulatory requirements, it is possible to determine the optimal ratio of marigold extract powder for specific needs. This knowledge is crucial for maximizing the benefits of marigold extract in various industries and ensuring the safety and quality of products containing it.

FAQ:

What are the main applications of marigold extract powder?

Marigold extract powder has several applications. It is widely used in the food industry as a natural colorant, adding a vibrant yellow - orange hue to various products. In the cosmetic field, it is valued for its antioxidant properties and is used in skincare products to help protect the skin from environmental damage. Additionally, in the pharmaceutical industry, it may have potential health - promoting properties and can be used in dietary supplements.

How does the ratio of marigold extract powder affect its applications?

Different ratios of marigold extract powder can have a significant impact on its applications. In the food industry, a specific ratio is required to achieve the desired color intensity without affecting the taste or safety of the product. In cosmetics, the ratio can influence the effectiveness of the antioxidant properties and the overall stability of the product. For pharmaceuticals, the right ratio is crucial for ensuring the proper dosage and bioavailability of the active compounds.

What factors influence the optimal ratio of marigold extract powder?

Several factors influence the optimal ratio of marigold extract powder. The source of the marigolds, including their variety and growing conditions, can play a role. The extraction method used also affects the composition of the extract powder, which in turn impacts the ideal ratio. Additionally, the intended application, whether it is for food, cosmetics, or pharmaceuticals, and the specific requirements of that application, such as stability, potency, and safety, are important factors.

How can one determine the right proportion of marigold extract powder for a specific need?

To determine the right proportion of marigold extract powder for a specific need, one must first consider the nature of the application. For food applications, it may be necessary to conduct taste tests and color - matching experiments at different ratios. In cosmetics, in - vitro and in - vivo tests can be used to evaluate the effectiveness of different ratios on skin properties. For pharmaceuticals, pre - clinical and clinical trials are often required to establish the appropriate dosage and ratio for safety and efficacy. Additionally, referring to existing industry standards and guidelines can also be helpful.

Are there any safety concerns related to different ratios of marigold extract powder?

Yes, there can be safety concerns related to different ratios of marigold extract powder. At very high ratios, there may be a risk of toxicity or adverse reactions, especially in pharmaceutical or dietary supplement applications. In the food industry, if the ratio is not properly controlled, it could lead to an excessive intake of certain components, which may not be safe for some consumers. In cosmetics, improper ratios might cause skin irritation or allergic reactions in some individuals.

Related literature

- Marigold Extract: Properties and Applications"

- "Optimizing the Use of Marigold Extract in the Food Industry"

- "The Role of Marigold Extract in Cosmetic Formulations"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Buckthorn bark extract

2024-12-10

-

Citrus bioflavonoids

2024-12-10

-

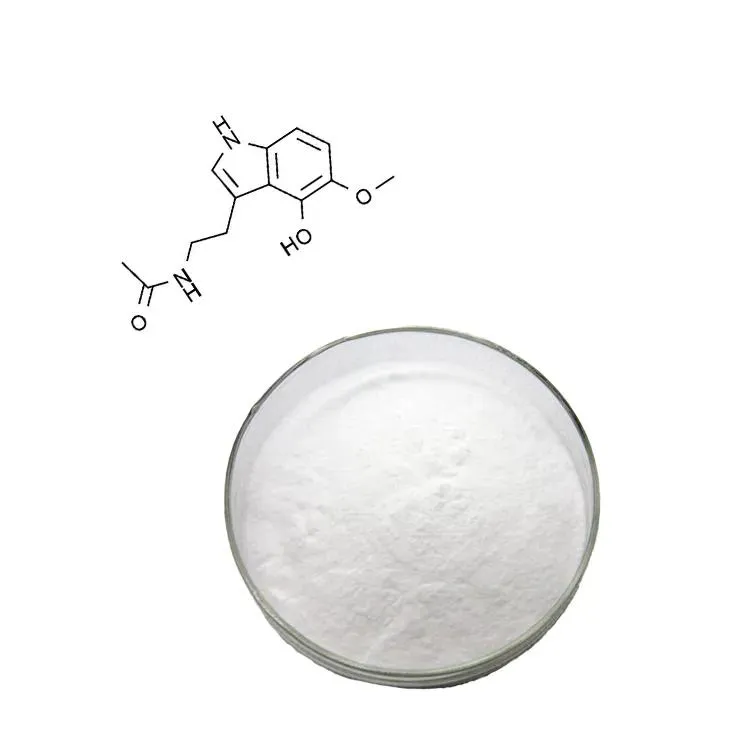

melatonin extract

2024-12-10

-

Mulberry Extract

2024-12-10

-

Hawthorn Extract

2024-12-10

-

Lavender Extract

2024-12-10

-

Dandelion Leaf Extract

2024-12-10

-

Yellow Pine Extract

2024-12-10

-

Avocado Extract Powder

2024-12-10

-

Rose Hip Extract

2024-12-10