- 0086-571-85302990

- sales@greenskybio.com

plant extract preparation protocol

2023-09-26

1. Selection of Plant Material

1. Selection of Plant Material

The selection of plant material is a crucial first step in the plant extract preparation protocol. This process involves identifying the appropriate plant species and ensuring that the specimens collected are of the highest quality for the intended application. Here are the key considerations for this stage:

1.1 Identification of Plant Species:

- The first step is to accurately identify the plant species from which the extracts will be prepared. This involves consulting botanical references, working with taxonomists, or using plant identification apps to confirm the species.

1.2 Ethnobotanical Knowledge:

- Leveraging traditional knowledge from indigenous communities can be invaluable, as they often have a deep understanding of the medicinal properties of local plants.

1.3 Seasonal Variation:

- The time of year when the plant material is collected can significantly affect the chemical composition of the plant. It's essential to collect samples during the optimal season when the plant's bioactive compounds are at their peak.

1.4 Plant Part Selection:

- Different parts of the plant (leaves, roots, bark, flowers, seeds, etc.) may contain varying levels of bioactive compounds. The selection of the plant part should be based on the desired extract's properties.

1.5 Health and Maturity of the Plant:

- Healthy, mature plants are preferred to ensure that the extracts are rich in the desired compounds. Diseased or stressed plants may have altered chemical profiles.

1.6 Environmental Factors:

- The environment in which the plant is grown can influence the composition of the extract. Factors such as soil type, exposure to pollutants, and climate conditions should be considered.

1.7 Legal and Ethical Considerations:

- It is important to ensure that the collection of plant material complies with local, national, and international laws regarding biodiversity conservation and sustainable harvesting practices.

1.8 Documentation:

- Proper documentation of the plant species, collection site, date, and collector's information is essential for traceability and future reference.

By carefully selecting the plant material, researchers and practitioners can ensure that the subsequent steps in the extraction process yield high-quality, bioactive plant extracts suitable for their intended applications. This foundational step sets the stage for the entire protocol, making it a critical component of successful plant extract preparation.

2. Collection and Storage of Plant Samples

2. Collection and Storage of Plant Samples

The collection and storage of plant samples are critical steps in the plant extract preparation protocol, as they directly influence the quality and integrity of the final product. This section will delve into the best practices for these processes.

2.1 Collection of Plant Samples

The selection of plant species and the timing of collection are paramount. Different plants have different bioactive compounds, which can vary depending on the season, time of day, and the plant's growth stage. Here are some guidelines for collection:

- Seasonal Variation: Choose the optimal season for the plant species. Some plants may have higher concentrations of bioactive compounds during specific seasons.

- Time of Day: Some plants may have higher levels of certain compounds at certain times of the day, such as early morning or late afternoon.

- Growth Stage: The stage of the plant's growth can affect the concentration of bioactive compounds. For example, flowering plants may have different chemical profiles than those in the vegetative stage.

- Ecological Factors: Consider the plant's environment, including soil type, exposure to sunlight, and potential pollutants, as these can affect the plant's chemistry.

2.2 Documentation

It is essential to document the collection process meticulously. Record the species name, collection date, location, and any other relevant ecological data. This information is vital for traceability and for future reference.

2.3 Handling and Transport

After collection, plant samples should be handled with care to prevent damage or contamination. Use clean tools and containers for collection and transport. Avoid direct sunlight and maintain a cool temperature during transport to preserve the integrity of the samples.

2.4 Storage Conditions

Proper storage is crucial to maintain the quality of plant samples. The following conditions should be considered:

- Temperature: Store samples in a cool environment, ideally at 4°C to slow down enzymatic and microbial activity.

- Humidity: Maintain a relative humidity that prevents drying out or mold growth.

- Light: Keep samples away from direct light, as some compounds can degrade under light exposure.

- Duration: Store samples for as short a time as possible before processing. If long-term storage is necessary, consider freezing or drying the samples.

2.5 Freezing and Drying

For long-term storage, consider the following methods:

- Freezing: Rapid freezing can help preserve the chemical composition of the plant samples. Use appropriate containers that are freezer-safe and seal them properly to prevent moisture loss.

- Drying: Drying can be done using air drying, oven drying, or freeze-drying. Each method has its advantages and disadvantages and should be chosen based on the specific requirements of the plant compounds being preserved.

2.6 Record Keeping

Maintain a detailed record of all samples, including storage conditions and any changes in the samples' state. This record is essential for quality control and future analysis.

In summary, the careful collection, handling, and storage of plant samples are fundamental to ensuring the quality of plant extracts. Adhering to these best practices will provide a solid foundation for the subsequent steps in the plant extract preparation protocol.

3. Preliminary Cleaning and Preparation

3. Preliminary Cleaning and Preparation

Before proceeding with the extraction process, it is crucial to ensure that the plant material is properly cleaned and prepared to obtain high-quality extracts. This step is essential for removing contaminants, reducing the risk of spoilage, and preserving the integrity of the plant's bioactive compounds. Here is a detailed overview of the preliminary cleaning and preparation process:

3.1 Selection of Plant Parts

The first step in the preparation process is to select the appropriate parts of the plant for extraction. Depending on the desired outcome, different parts such as leaves, roots, stems, flowers, or fruits may be chosen. It is important to identify the plant parts that are rich in the target compounds.

3.2 Thorough Washing

Plant materials are often contaminated with soil, dust, and microorganisms. Thorough washing with clean water is necessary to remove these contaminants. Some protocols may also include the use of mild detergents or sanitizing solutions to further reduce microbial load, but care must be taken not to introduce new contaminants or damage the plant material.

3.3 Removal of Non-Target Materials

After washing, it is important to remove any non-target materials such as dead leaves, stems, or other debris that may not contribute to the desired extract properties. This step helps to ensure that the final product is concentrated and free from unwanted substances.

3.4 Cutting and Size Reduction

To increase the surface area and facilitate the extraction process, the plant material should be cut or ground into smaller pieces. The size of the pieces can vary depending on the extraction technique used. For instance, some methods may require fine powders, while others may work better with larger chunks.

3.5 Drying (if necessary)

In some cases, the plant material may need to be dried to reduce its moisture content, which can help prevent spoilage and improve the efficiency of the extraction process. Drying can be done using various methods such as air drying, oven drying, or freeze drying. The choice of drying method should be based on the sensitivity of the plant compounds to heat or other conditions.

3.6 Soaking (if applicable)

For certain extraction techniques, particularly those involving solvents, the plant material may be soaked in the solvent or a mixture of solvents to initiate the extraction process. This step can help to break down cell walls and release the bioactive compounds more effectively.

3.7 Documentation and Labeling

Throughout the cleaning and preparation process, it is important to document each step and label the plant samples appropriately. This includes recording the type of plant, part used, collection date, and any treatments applied. Proper documentation and labeling are crucial for traceability and quality control purposes.

3.8 Quality Assessment

Before moving on to the extraction phase, a preliminary quality assessment of the prepared plant material should be conducted. This may involve visual inspection, organoleptic tests, or preliminary chemical analyses to ensure that the material is suitable for further processing.

By following these steps, researchers and practitioners can ensure that the plant material is properly prepared for extraction, maximizing the yield and quality of the final product. Proper cleaning and preparation are foundational to the success of any plant extract preparation protocol.

4. Extraction Techniques

4. Extraction Techniques

Extraction techniques are a critical step in the preparation of plant extracts, as they determine the efficiency of the process and the quality of the final product. Several methods can be employed to extract bioactive compounds from plant materials, each with its own advantages and limitations. Here, we discuss some of the most commonly used extraction techniques:

4.1 Solvent Extraction

Solvent extraction is a widely used method that involves the use of solvents to dissolve and separate the desired compounds from plant material. The choice of solvent is crucial and depends on the polarity of the target compounds. Common solvents include water, ethanol, methanol, acetone, and dichloromethane.

4.2 Maceration

Maceration is a simple and traditional method where plant material is soaked in a solvent for an extended period, allowing the solvent to penetrate the plant tissue and dissolve the bioactive compounds. This method is often used for large-scale extractions.

4.3 Soxhlet Extraction

The Soxhlet extraction method uses a continuous extraction process, where the solvent is heated, passed through the plant material, and then condensed back into the extraction vessel. This process is repeated multiple times, enhancing the extraction efficiency.

4.4 Ultrasound-Assisted Extraction (UAE)

Ultrasound-assisted extraction utilizes ultrasonic waves to disrupt plant cell walls, facilitating the release of bioactive compounds into the solvent. This method is known for its efficiency, speed, and ability to extract a wide range of compounds.

4.5 Supercritical Fluid Extraction (SFE)

Supercritical fluid extraction uses supercritical fluids, typically carbon dioxide, which have properties between a liquid and a gas. This method allows for selective extraction of compounds based on their solubility in the supercritical fluid.

4.6 Pressurized Liquid Extraction (PLE)

Also known as accelerated solvent extraction, PLE uses high pressure and temperature to enhance the extraction process. This method is efficient and can be tailored to specific compounds by adjusting the pressure and temperature.

4.7 Microwave-Assisted Extraction (MAE)

Microwave-assisted extraction employs microwave energy to heat the solvent, which accelerates the extraction process. This method is known for its rapid extraction time and high extraction yield.

4.8 Cold Pressing

Cold pressing is a mechanical method used to extract oils and other compounds from plant materials without the use of heat or solvents. This method is particularly suitable for extracting volatile compounds that may degrade under heat.

4.9 Enzymatic Extraction

Enzymatic extraction involves the use of enzymes to break down plant cell walls and release the bioactive compounds. This method is gentle and can be used to extract heat-sensitive compounds.

4.10 Green Extraction Techniques

Green extraction techniques focus on using environmentally friendly solvents and methods to minimize the environmental impact of the extraction process. Examples include the use of ionic liquids, deep eutectic solvents, and aqueous two-phase systems.

Each extraction technique has its own set of parameters that need to be optimized for the specific plant material and target compounds. The choice of extraction method depends on factors such as the nature of the plant material, the desired compounds, the scale of the operation, and the available resources.

5. Filtration and Concentration

5. Filtration and Concentration

Filtration and concentration are critical steps in the plant extract preparation protocol, ensuring the purity and potency of the final product. These processes help to remove unwanted solid particles and reduce the volume of the liquid extract, thereby increasing the concentration of the bioactive compounds.

5.1 Filtration Techniques

There are several filtration methods that can be employed depending on the nature of the plant material and the desired outcome:

- Gravity Filtration: This is a simple and cost-effective method where the extract is allowed to pass through a filter medium under the influence of gravity. It is suitable for coarse filtration to remove larger particles.

- Vacuum Filtration: Utilizing a vacuum to speed up the filtration process, this method is more efficient for fine particles and can be used with filter papers or membranes.

- Membrane Filtration: Involves the use of semi-permeable membranes that allow certain molecules to pass through while retaining others based on size. It is highly effective for separating colloidal particles and microorganisms.

- Ultrafiltration: A type of membrane filtration that uses pressure to force the liquid through a membrane with smaller pore sizes, suitable for separating macromolecules from smaller ones.

5.2 Concentration Methods

After filtration, the extract may need to be concentrated to increase the concentration of the desired compounds:

- Evaporation: This can be done using a rotary evaporator under reduced pressure and controlled temperature to remove solvents without degrading heat-sensitive compounds.

- Lyophilization (Freeze Drying): A process that involves freezing the extract and then reducing the surrounding pressure to allow the frozen water to sublime directly from the solid to the gas phase, leaving a dry, porous cake of the extract.

- Distillation: Applicable for volatile compounds, this method separates components based on differences in boiling points.

- Molecular Distillation: A gentle distillation technique that operates under high vacuum and low temperature, preserving the integrity of sensitive compounds.

5.3 Considerations for Filtration and Concentration

- Temperature Control: It is crucial to maintain appropriate temperatures during these processes to prevent the degradation of heat-sensitive bioactive compounds.

- Purity: The choice of filter material should ensure that it does not react with the extract or introduce contaminants.

- Scale-up: Methods should be scalable from laboratory to industrial production while maintaining consistent quality and efficiency.

5.4 Quality Assessment Post-Filtration and Concentration

After filtration and concentration, it is essential to assess the quality of the extracts to ensure they meet the desired specifications:

- Bioactivity Assays: To confirm the presence and activity of the target compounds.

- Spectral Analysis: Techniques such as UV-Vis, HPLC, or GC-MS can be used to characterize the composition of the extract.

- Physical Properties: Checking for the correct consistency, color, and absence of visible impurities.

By carefully executing the filtration and concentration steps, researchers and manufacturers can produce high-quality plant extracts that are suitable for a wide range of applications, from pharmaceuticals to cosmetics and food products.

6. Drying and Storage of Extracts

6. Drying and Storage of Extracts

The drying and storage of plant extracts is a critical step in the preparation protocol, ensuring the preservation of bioactive compounds and the stability of the extracts for future use. Here are the key points to consider in this process:

6.1 Drying Techniques

- Evaporation: The most common method, where the solvent is removed by evaporation under controlled temperature and pressure conditions.

- Lyophilization (Freeze-drying): This technique involves freezing the extract and then reducing the surrounding pressure to allow the frozen water to sublime directly from the solid to the gas phase, leaving a dry, porous product.

- Spray Drying: A method where the extract is sprayed into a hot gas stream, leading to rapid evaporation of the solvent and formation of dry particles.

- Vacuum Drying: The use of vacuum to lower the boiling point of the solvent, allowing for evaporation at lower temperatures, which is beneficial for heat-sensitive compounds.

6.2 Considerations for Drying

- The choice of drying method should be based on the nature of the bioactive compounds present in the extract to avoid degradation.

- The drying process should be carried out under sterile conditions to prevent microbial contamination.

- The temperature and duration of the drying process must be optimized to ensure complete removal of the solvent without damaging the extract.

6.3 Storage Conditions

- Temperature: Extracts should be stored at low temperatures, typically 4°C or -20°C, to minimize degradation of the bioactive compounds.

- Humidity: Dry conditions are essential to prevent the growth of microorganisms and the reabsorption of moisture by the extract.

- Light: Exposure to light can cause photochemical degradation of some compounds; thus, extracts should be stored in light-protected containers.

- Atmosphere: Oxygen can also contribute to the oxidation of certain compounds; inert gas atmospheres (e.g., nitrogen or argon) may be used for sensitive extracts.

6.4 Packaging Materials

- The choice of packaging material is crucial to prevent contamination and ensure the integrity of the extract.

- Materials should be chemically inert, non-toxic, and resistant to the conditions of storage (e.g., temperature, humidity).

- Common packaging materials include glass vials, plastic bags, and specialized desiccated containers.

6.5 Documentation and Labeling

- Accurate documentation of the drying and storage conditions, as well as the date of preparation and storage, is essential for traceability and quality assurance.

- Each container should be clearly labeled with information such as the plant source, extract type, concentration, and storage conditions.

6.6 Periodic Quality Checks

- Regular quality checks should be performed to assess the stability and potency of the extracts over time.

- This may involve retesting for bioactivity, chemical composition, and the presence of contaminants.

Proper drying and storage of plant extracts are essential to maintain their quality and ensure their efficacy in various applications. By following these guidelines, researchers and practitioners can preserve the valuable properties of plant extracts for future use in research, pharmaceuticals, cosmetics, and other industries.

7. Quality Control and Analysis

7. Quality Control and Analysis

Quality control and analysis are critical steps in the plant extract preparation protocol to ensure the safety, efficacy, and consistency of the final product. These steps are essential for verifying the chemical composition, purity, and potency of the extracts, as well as for detecting any potential contaminants or impurities.

7.1 Chemical Analysis

Chemical analysis involves the use of various analytical techniques to identify and quantify the active compounds present in the plant extracts. Common methods include:

1. High-Performance Liquid Chromatography (HPLC): This technique is used to separate, identify, and quantify individual compounds in a complex mixture.

2. Gas Chromatography-Mass Spectrometry (GC-MS): This method is particularly useful for analyzing volatile compounds and can provide detailed information about the molecular structure of the compounds.

3. Nuclear Magnetic Resonance (NMR) Spectroscopy: NMR can provide detailed information about the molecular structure and dynamics of the compounds in the extract.

4. Ultraviolet-Visible (UV-Vis) Spectroscopy: This technique is used to study the electronic transitions in molecules and can be used to determine the concentration of certain compounds.

7.2 Physical and Sensory Analysis

Physical and sensory analysis assesses the physical properties and sensory characteristics of the plant extracts, such as color, viscosity, taste, and aroma. This can be done through:

1. Color Measurement: Using colorimeters or spectrophotometers to measure the color intensity and hue of the extracts.

2. Viscosity Measurement: Using viscometers to determine the flow properties of the extracts.

3. Taste and Aroma Profiling: Subjective assessments by trained panelists to evaluate the sensory attributes of the extracts.

7.3 Microbiological Analysis

Microbiological analysis is performed to ensure the extracts are free from harmful microorganisms, such as bacteria, yeast, and mold. Common methods include:

1. Plate Count Agar: A culture medium used to determine the total number of viable microorganisms present in the extract.

2. Membrane Filtration: A technique used to separate microorganisms from the extract and then enumerate them on a culture medium.

3. Molecular Techniques: Such as PCR (Polymerase Chain Reaction) to detect specific pathogens or spoilage organisms in the extract.

7.4 Heavy Metal and Pesticide Residue Analysis

Heavy metal and pesticide residue analysis is crucial to ensure the safety of the plant extracts. Techniques used for this purpose include:

1. Atomic Absorption Spectroscopy (AAS): Measures the concentration of specific heavy metals in the extract.

2. Inductively Coupled Plasma Mass Spectrometry (ICP-MS): A highly sensitive technique for detecting trace amounts of heavy metals.

3. Gas Chromatography (GC): Used to analyze pesticide residues in the extracts.

7.5 Standardization and Validation

Standardization ensures that the plant extracts meet predefined quality criteria, while validation confirms the accuracy and reliability of the analytical methods used. This includes:

1. Establishment of Quality Standards: Defining the acceptable ranges for active compounds, physical properties, and safety parameters.

2. Method Validation: Demonstrating that the analytical methods are accurate, precise, and specific for the compounds of interest.

7.6 Good Laboratory Practice (GLP)

Adhering to Good Laboratory Practice guidelines ensures the integrity and reliability of the quality control and analysis process. This includes maintaining proper documentation, following standardized operating procedures, and ensuring the competency of personnel involved in the analysis.

In conclusion, quality control and analysis are integral components of the plant extract preparation protocol. They ensure the safety, efficacy, and consistency of the extracts, providing valuable information for further research, product development, and regulatory compliance. As the demand for natural products continues to grow, the importance of robust quality control and analysis will only increase, driving the need for innovative and efficient analytical methods.

8. Applications of Plant Extracts

8. Applications of Plant Extracts

Plant extracts have a wide range of applications across various industries due to their rich bioactive compounds. These applications can be broadly categorized into the following areas:

Pharmaceutical Industry:

Plant extracts are extensively used in the development of new drugs and traditional medicines. They serve as sources of active pharmaceutical ingredients, which can be used to treat a variety of ailments, including chronic and infectious diseases.

Nutraceutical Industry:

Nutraceuticals are products derived from food sources with extra health benefits, including the prevention and treatment of disease. Plant extracts are key components in many nutraceutical products, offering consumers natural health supplements.

Cosmetics and Personal Care:

The cosmetic industry utilizes plant extracts for their antioxidant, anti-inflammatory, and skin-soothing properties. They are incorporated into skincare products, hair care products, and personal care items to enhance their efficacy and appeal to consumers seeking natural ingredients.

Agriculture:

Plant extracts are used as natural pesticides and growth promoters in sustainable agriculture. They can help control pests and diseases in crops without causing harm to the environment or leaving chemical residues.

Food and Beverage Industry:

Flavors, colors, and preservatives derived from plant extracts are used in the food and beverage industry. They provide natural alternatives to synthetic additives, catering to the growing consumer demand for natural and organic products.

Environmental Applications:

Plant extracts can be used for environmental remediation, such as the treatment of wastewater and soil decontamination. Certain plant extracts have the ability to absorb or break down pollutants, making them valuable tools in environmental conservation.

Research and Development:

Plant extracts are a rich source of bioactive compounds for research purposes. They are used in laboratories to study their potential health benefits, mechanisms of action, and interactions with other substances.

Traditional Medicine:

Many cultures have a long history of using plant extracts in traditional medicine. These extracts are still widely used today, either in their traditional forms or as part of modernized formulations.

Industrial and Commercial Products:

Plant extracts are also used in various industrial applications, such as the production of dyes, fragrances, and other specialty chemicals.

In conclusion, the applications of plant extracts are diverse and expanding, driven by the growing interest in natural products and the need for sustainable solutions across different sectors. As research continues to uncover new properties and potential uses for plant extracts, their applications are expected to broaden even further.

9. Conclusion and Future Perspectives

9. Conclusion and Future Perspectives

In conclusion, the preparation of plant extracts is a multifaceted process that requires careful consideration at each step, from the selection of plant material to the final applications of the extracts. The protocols outlined in this article provide a comprehensive guide for researchers and practitioners in the field of phytochemistry and botanical medicine. The successful extraction of bioactive compounds from plants is contingent upon adherence to these protocols, ensuring the integrity and efficacy of the resulting extracts.

As we look to the future, there are several key areas of development and innovation in the field of plant extract preparation:

1. Technological Advancements: The integration of advanced technologies such as high-throughput screening, nanotechnology, and automated extraction systems can enhance the efficiency and precision of the extraction process.

2. Sustainability: With increasing awareness of environmental issues, there is a growing need to develop sustainable extraction methods that minimize waste and reduce the environmental footprint of the process.

3. Standardization: Establishing standardized protocols for the preparation of plant extracts will facilitate more reliable and reproducible results, which is crucial for the development of plant-based medicines and nutraceuticals.

4. Quality Control: The development of more sophisticated analytical techniques will improve the quality control of plant extracts, ensuring their safety and efficacy.

5. Regulatory Compliance: As the use of plant extracts in various industries expands, there will be a greater need for regulatory frameworks that govern their production and use, ensuring consumer safety and product quality.

6. Interdisciplinary Research: Collaboration between biologists, chemists, pharmacologists, and other experts can lead to a deeper understanding of the complex interactions between plant compounds and their potential therapeutic applications.

7. Clinical Trials and Applications: Further research into the clinical efficacy of plant extracts is essential to validate their use in medicine and to expand their applications in healthcare.

8. Ethnobotanical Knowledge: The integration of traditional knowledge from indigenous cultures can provide valuable insights into the use of plant extracts, potentially leading to the discovery of new therapeutic agents.

9. Public Awareness and Education: Increasing public awareness about the benefits and proper use of plant extracts can promote their acceptance and integration into mainstream medicine and health practices.

The future of plant extract preparation is promising, with the potential to contribute significantly to the development of new medicines, the enhancement of food products, and the improvement of overall human health. As research continues to uncover the vast potential of plants, the protocols and practices in this field will undoubtedly evolve, driven by scientific innovation and the pursuit of excellence in botanical applications.

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

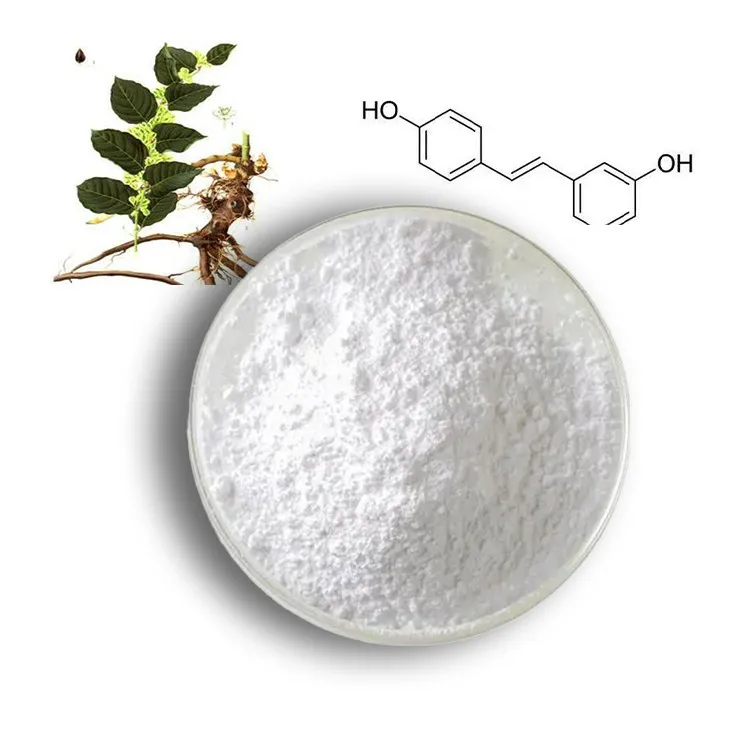

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Troxerutin

2023-09-26

-

Saponin Extract

2023-09-26

-

Nettle leaf extract

2023-09-26

-

Panax Ginseng Leaf Extract

2023-09-26

-

Tongkat Ali Extract Powder

2023-09-26

-

Moringa powder

2023-09-26

-

Chasteberry Extract

2023-09-26

-

Kidney Bean Extract

2023-09-26

-

Red Vine Extract

2023-09-26

-

Resveratrol extract

2023-09-26