- 0086-571-85302990

- sales@greenskybio.com

Two Bases of Peppermint Oil Quality: Potency and Purity.

2024-12-11

1. Introduction

Peppermint Oil has been widely used in various industries, including cosmetics, food, and medicine. Its quality is of utmost importance, as it directly affects the performance and safety of the products it is incorporated into. The two fundamental aspects that determine the quality of Peppermint Oil are potency and purity.

2. Potency of Peppermint Oil

2.1 Definition and Significance

Potency refers to the strength and efficacy of peppermint oil. It is a measure of the active compounds present in the oil that are responsible for its characteristic properties. A high - potency peppermint oil contains a higher concentration of these active compounds, which can lead to more pronounced effects.

In the cosmetics industry, for example, peppermint oil is often used for its cooling and refreshing sensations. A more potent oil can provide a stronger and longer - lasting cooling effect on the skin, enhancing the overall user experience. In the food industry, the potency of peppermint oil can influence the flavor intensity. A highly potent oil can add a more distinct and refreshing minty flavor to products such as candies, chewing gums, and beverages.

2.2 Factors Affecting Potency

- Plant Source: The species of peppermint plant used to extract the oil can significantly affect its potency. Different species may have varying levels of active compounds. For instance, Mentha × piperita is a commonly used species for peppermint oil production, but within this species, there can be differences in genetic makeup that result in differences in potency.

- Geographical Origin: The location where the peppermint plants are grown can also impact potency. Factors such as soil quality, climate, and altitude can influence the growth and development of the plants, and consequently, the concentration of active compounds in the oil. Peppermint plants grown in certain regions with optimal growing conditions may produce more potent oils.

- Harvesting Time: The time at which the peppermint plants are harvested is crucial. If the plants are harvested too early or too late, the concentration of active compounds may be sub - optimal. Generally, peppermint plants are harvested when they are in full bloom, as this is when the levels of active compounds are typically at their highest.

- Extraction Method: The method used to extract the peppermint oil from the plant material can also affect its potency. Common extraction methods include steam distillation and solvent extraction. Steam distillation is a widely used method as it is relatively gentle and can preserve the integrity of the active compounds. However, improper steam distillation parameters, such as too high or too low temperature or pressure, can lead to a loss of potency.

3. Purity of Peppermint Oil

3.1 Definition and Importance

Purity refers to the absence of contaminants and adulterants in the peppermint oil. A pure peppermint oil is one that contains only the natural components derived from the peppermint plant. Purity is essential for several reasons.

First, it guarantees the authenticity of the peppermint oil. Consumers expect to get a product that is truly peppermint - based, especially when they are purchasing products for their natural or herbal properties. Second, purity is crucial for safety. Impure peppermint oil may contain harmful substances that can cause allergic reactions, skin irritations, or other adverse health effects. In the food and pharmaceutical industries, purity is also important to ensure the stability and effectiveness of the final products.

3.2 Common Contaminants and Adulterants

- Other Essential Oils: Some unscrupulous producers may add other, cheaper essential oils to peppermint oil to cut costs. For example, adding a small amount of eucalyptus oil, which has a similar minty smell, can be difficult to detect for the untrained eye or nose. However, this can change the overall properties and quality of the peppermint oil.

- Synthetic Compounds: Synthetic additives may be introduced during the production process. These can include artificial flavors or preservatives that are not part of the natural peppermint oil composition. Their presence can not only affect the purity but also pose potential health risks.

- Residual Solvents: If solvent extraction is used to obtain the peppermint oil, improper removal of the solvent can leave behind residual solvents in the oil. These solvents can be toxic and are not meant to be present in a pure peppermint oil product.

- Heavy Metals: During the growth of peppermint plants, they may absorb heavy metals from the soil if the soil is contaminated. These heavy metals can then be present in the extracted peppermint oil, which is a significant concern as they can have harmful effects on human health.

4. Analysis and Testing for Potency and Purity

4.1 Analytical Methods for Potency

- Gas Chromatography - Mass Spectrometry (GC - MS): This is a powerful analytical technique that can identify and quantify the various components in peppermint oil. By separating the different compounds in the oil based on their volatility and mass - to - charge ratio, GC - MS can accurately determine the concentration of active compounds such as menthol and menthone, which are key indicators of potency.

- High - Performance Liquid Chromatography (HPLC): HPLC is another commonly used method for analyzing the potency of peppermint oil. It can separate and measure the levels of different compounds in the oil, providing detailed information about the composition and concentration of active ingredients.

4.2 Testing for Purity

- Organoleptic Evaluation: This involves using the senses of smell and taste to detect any off - odors or flavors that may indicate the presence of contaminants or adulterants. However, this method is subjective and requires trained personnel.

- Physical and Chemical Tests: These tests can include measuring the density, refractive index, and solubility of the peppermint oil. Deviations from the normal values for pure peppermint oil can suggest the presence of impurities. Chemical tests can also be used to detect specific contaminants, such as heavy metals or residual solvents.

- Chromatographic Techniques: Similar to the methods used for analyzing potency, chromatographic techniques like GC - MS and HPLC can also be used to detect impurities in peppermint oil. By comparing the chromatogram of the sample with that of a pure reference standard, any additional peaks corresponding to contaminants can be identified.

5. Maintaining Potency and Purity in Production

5.1 Good Agricultural Practices (GAP)

To ensure high - quality peppermint oil, it is essential to follow good agricultural practices during the cultivation of peppermint plants.

- Proper soil management, including soil testing and fertilization, to ensure optimal nutrient availability for the plants.

- Appropriate irrigation techniques to provide the right amount of water at the correct times, as both over - watering and under - watering can affect plant growth and the concentration of active compounds.

- Use of pest and disease control methods that are environmentally friendly and do not contaminate the plants or the soil, as the use of harmful pesticides can lead to the presence of residues in the peppermint oil.

5.2 Quality Control in Extraction and Processing

During the extraction and processing of peppermint oil, strict quality control measures should be implemented.

- For extraction methods such as steam distillation, ensuring that the equipment is properly calibrated and the operating parameters (temperature, pressure, etc.) are optimized to preserve the potency of the oil.

- Regular cleaning and maintenance of the extraction and processing equipment to prevent cross - contamination with other substances.

- Testing of the intermediate and final products at various stages of production to ensure that the purity and potency requirements are met.

6. Conclusion

Potency and purity are two essential bases for the quality of peppermint oil. Potency determines the strength and effectiveness of the oil in various applications, while purity ensures its authenticity and safety. Understanding the factors that affect potency and purity, as well as implementing appropriate analysis, testing, and production control measures, is crucial for the production of high - quality peppermint oil. As the demand for natural and high - quality products continues to grow, ensuring the quality of peppermint oil based on these two aspects will be increasingly important in the industries where it is used.

FAQ:

1. What is the significance of potency in peppermint oil quality?

Potency in peppermint oil is very important as it represents the strength and efficacy of the oil. High - potency peppermint oil is more desirable in the market because it has the potential to offer strong sensory experiences in products such as cosmetics and food.

2. How does purity affect the quality of peppermint oil?

Purity is crucial for peppermint oil quality. It ensures the authenticity and safety of the oil. If the oil is impure, it may lead to unwanted side effects or reduced performance.

3. Can high - potency peppermint oil be used in all products?

While high - potency peppermint oil has its advantages, it may not be suitable for all products. Different products have different requirements regarding the strength of the peppermint oil. For example, some sensitive - skin - targeted cosmetics may need a lower - potency peppermint oil to avoid irritation.

4. How can one determine the purity of peppermint oil?

There are several methods to determine the purity of peppermint oil. Laboratory analysis can be used to detect the presence of impurities such as other oils or chemicals. Additionally, factors like the source of the oil, the extraction method, and the reputation of the supplier can also give an indication of its purity.

5. Are there any industry standards for peppermint oil potency and purity?

Yes, there are industry standards for peppermint oil potency and purity. These standards are set to ensure the quality and consistency of peppermint oil in the market. For example, certain organizations may define minimum potency levels and acceptable impurity limits for peppermint oil used in different applications.

Related literature

- Analysis of Peppermint Oil Potency in Cosmetic Applications"

- "Purity Assessment of Peppermint Oil: A Comprehensive Review"

- "The Role of Potency and Purity in Defining Peppermint Oil Quality"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

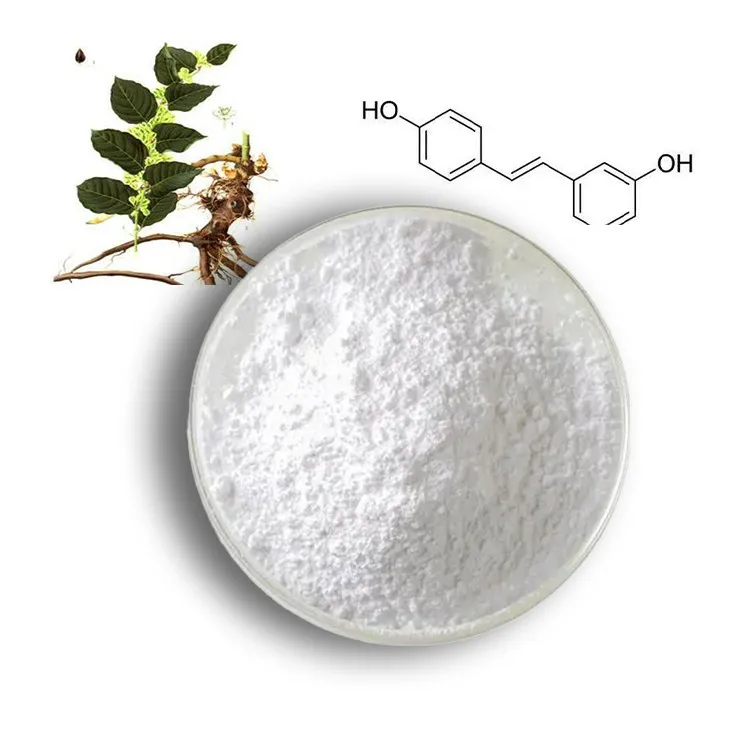

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Black Pepper Extract

2024-12-11

-

Carrageenan Extract Powder

2024-12-11

-

Eyebright Extract

2024-12-11

-

Kelp Extract Powder

2024-12-11

-

Resveratrol extract

2024-12-11

-

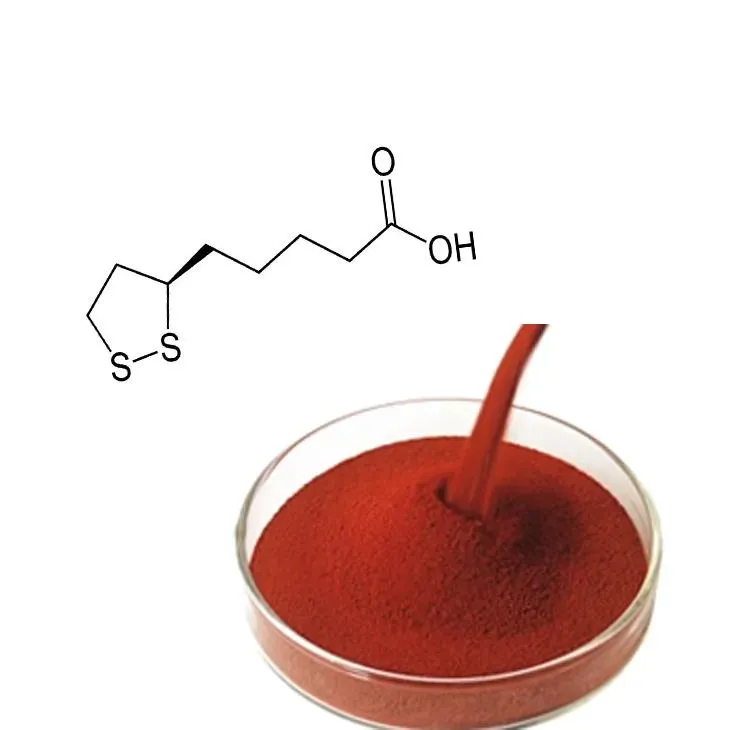

Astaxanthin

2024-12-11

-

Horse Chestnut Extract

2024-12-11

-

Cranberry Extract

2024-12-11

-

Acerola Extract

2024-12-11

-

Pomegranate Extract

2024-12-11