- 0086-571-85302990

- sales@greenskybio.com

Production of Alisma orientale Extract: A Complete Guide for Consumers and Manufacturers

2024-12-10

1. Introduction to Alisma plantago - aquatica

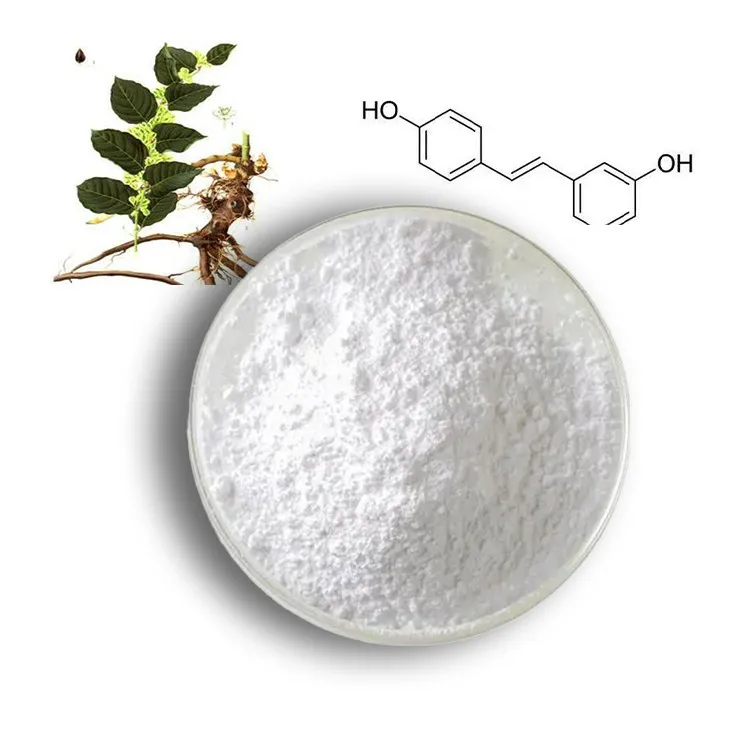

Alisma plantago - aquatica, commonly known as water - plantain, is a perennial aquatic or semi - aquatic plant. It is native to various regions across the world, including Asia, Europe, and North America. This plant has a long history of use in traditional medicine systems, such as Traditional Chinese Medicine (TCM).

The plant typically grows in wetland habitats, such as marshes, ponds, and along the banks of slow - moving streams. It has broad, lance - shaped leaves and small, white or pale pink flowers. Understanding the natural habitat and characteristics of Alisma plantago - aquatica is crucial for both consumers and producers involved in the production of its extract.

2. Production Process of Alisma plantago - aquatica Extract

2.1 Harvesting

The first step in the production of Alisma plantago - aquatica extract is the harvesting of the plant. Harvesting time is of great importance. It is usually carried out during the plant's growth period when the active ingredients are at their peak levels. Typically, this occurs in the late summer or early autumn.

When harvesting, only the mature plants are selected. Care should be taken to avoid damaging the surrounding environment and other non - target plants. The harvested plants are then carefully cleaned to remove any dirt, debris, or other contaminants.

2.2 Drying

After harvesting, the plants need to be dried. Drying helps to preserve the plant material and concentrate the active ingredients. There are different drying methods available, such as air drying and low - temperature drying.

Air drying is a traditional method where the plants are spread out in a well - ventilated area away from direct sunlight. This method is relatively simple but may take longer. On the other hand, low - temperature drying using specialized drying equipment can speed up the process while maintaining the quality of the plant material. The dried plants are then stored in a cool, dry place until further processing.

2.3 Extraction

The extraction process is a key step in obtaining the Alisma plantago - aquatica extract. There are several extraction methods, including solvent extraction and supercritical fluid extraction.

Solvent extraction involves using solvents such as ethanol or methanol to dissolve the active ingredients from the dried plant material. The solvent - plant mixture is then filtered and the solvent is evaporated to obtain the extract. However, this method requires careful control of solvent quality and extraction conditions to ensure the purity and safety of the extract.

Supercritical fluid extraction is a more advanced method. Supercritical carbon dioxide is often used as the extraction fluid. This method has the advantage of being more environmentally friendly and can produce a high - quality extract with a relatively pure composition of active ingredients.

3. Quality Control in Alisma plantago - aquatica Extract Production

3.1 Raw Material Quality

Ensuring the quality of the raw material, i.e., the Alisma plantago - aquatica plants, is fundamental. The plants should be sourced from reliable suppliers or harvested in a sustainable and controlled manner.

Quality control measures at this stage may include checking for the correct species, absence of contaminants (such as pesticides or heavy metals), and the overall health and maturity of the plants.

3.2 Extraction Process Monitoring

During the extraction process, strict monitoring is required. For solvent extraction, parameters such as solvent concentration, extraction time, and temperature need to be carefully controlled.

In supercritical fluid extraction, factors like pressure, temperature, and flow rate of the supercritical fluid must be maintained within the optimal range to ensure consistent quality of the extract. Regular sampling and analysis of the extract during the extraction process can help detect any deviations and make timely adjustments.

3.3 Final Product Testing

Once the extract is obtained, comprehensive testing is carried out on the final product. This includes testing for the presence and concentration of active ingredients, which can be done using techniques such as high - performance liquid chromatography (HPLC).

Additionally, safety tests for contaminants (including microbial contamination), stability tests to determine the shelf - life of the extract, and other relevant quality parameters are also performed. Only products that meet the established quality standards are allowed to enter the market.

4. Applications of Alisma plantago - aquatica Extract

4.1 In Traditional Medicine

In traditional medicine systems like TCM, Alisma plantago - aquatica extract has been used for various medicinal purposes. It is often associated with functions such as promoting diuresis (increasing urine production), which is believed to help in treating conditions related to fluid retention in the body, such as edema.

It may also be used in formulations to address certain kidney - related disorders, although modern scientific research is still exploring the exact mechanisms underlying these traditional uses.

4.2 In the Cosmetic Industry

The extract has found applications in the cosmetic industry. Its potential benefits for skin health, such as moisturizing and anti - inflammatory properties, have led to its inclusion in skincare products.

For example, it may be used in creams, lotions, and serums to improve skin hydration and soothe irritated skin. Some cosmetic companies are also exploring its potential in anti - aging products due to its antioxidant properties.

4.3 In the Nutraceutical Field

In the nutraceutical field, Alisma plantago - aquatica extract is being studied for its potential health - promoting effects. It may be used as an ingredient in dietary supplements, aiming to provide benefits such as supporting kidney function or overall fluid balance in the body.

However, more research is needed to fully understand its efficacy and safety when used as a nutraceutical, and regulatory compliance is crucial in this area.

5. Market Trends of Alisma plantago - aquatica Extract

5.1 Growing Interest in Natural Products

There is a global trend towards natural products, and Alisma plantago - aquatica extract is no exception. Consumers are increasingly seeking natural alternatives for health and beauty products, which has led to a growing demand for this extract.

This trend is driven by factors such as concerns about the side effects of synthetic chemicals and a preference for more sustainable and plant - based ingredients.

5.2 Research and Development

Ongoing research and development efforts are also influencing the market for Alisma plantago - aquatica extract. As more scientific studies are conducted to explore its potential applications and health benefits, new products and uses are likely to emerge.

This research may lead to improved extraction methods, enhanced product formulations, and a better understanding of its safety and efficacy, which will in turn drive market growth.

5.3 Regulatory Environment

The regulatory environment plays a significant role in the market for Alisma plantago - aquatica extract. Different countries and regions have varying regulations regarding the production, marketing, and use of herbal extracts.

Producers need to stay informed about these regulations to ensure compliance. For example, in the nutraceutical and pharmaceutical sectors, strict regulatory requirements are in place to ensure product safety and quality.

6. Conclusion

The production of Alisma plantago - aquatica extract involves multiple steps, from harvesting to extraction, with strict quality control throughout the process. The extract has diverse applications in traditional medicine, cosmetics, and the nutraceutical field.

Market trends, such as the growing interest in natural products and ongoing research, are creating opportunities for the development and expansion of the Alisma plantago - aquatica extract market. However, producers must also be aware of and comply with the regulatory environment to ensure the sustainable growth of this industry.

FAQ:

What are the main methods for producing Alisma plantago - aquatica extract?

There are several common methods for producing Alisma plantago - aquatica extract. One is the solvent extraction method, where solvents like ethanol or water are used to extract the active compounds from the Alisma plantago - aquatica. Another method could be supercritical fluid extraction, which often uses carbon dioxide under supercritical conditions to selectively extract the desired components. Maceration, a traditional method, is also used where the plant material is soaked in a solvent for an extended period to allow the extraction of the active substances.

How is quality control ensured during the production of Alisma plantago - aquatica extract?

Quality control in the production of Alisma plantago - aquatica extract involves multiple aspects. Firstly, the raw materials need to be carefully sourced and inspected for authenticity and purity. During the extraction process, parameters such as temperature, pressure (in the case of certain extraction methods), and extraction time are closely monitored. After extraction, the extract is tested for the presence and concentration of key active compounds using techniques like HPLC (High - Performance Liquid Chromatography). Microbiological tests are also carried out to ensure the absence of harmful microorganisms.

What are the common applications of Alisma plantago - aquatica extract?

Alisma plantago - aquatica extract has various applications. In traditional medicine, it has been used for its diuretic properties, helping to increase urine output. It is also being explored for its potential anti - inflammatory effects, which could be useful in treating certain inflammatory conditions. In the cosmetic industry, extracts may be used in skincare products due to its potential antioxidant properties that can help protect the skin from oxidative damage.

What are the current market trends for Alisma plantago - aquatica extract?

The market for Alisma plantago - aquatica extract is showing some interesting trends. There is a growing demand in the natural health product sector, as consumers are increasingly interested in herbal remedies. The use of Alisma plantago - aquatica extract in dietary supplements is on the rise. Additionally, with the increasing focus on sustainable and natural ingredients in the cosmetic and personal care industries, the extract is also finding more applications in these areas. However, regulatory requirements and quality standards are becoming more stringent, which is influencing the production and marketing of the extract.

Are there any potential side effects associated with Alisma plantago - aquatica extract?

While Alisma plantago - aquatica has been used traditionally, there can be potential side effects. High doses or long - term use may cause gastrointestinal disturbances such as nausea, vomiting, or diarrhea. Also, as with any herbal product, there may be interactions with medications, so it is important for consumers to consult a healthcare provider if they are taking other drugs while using products containing this extract.

Related literature

- Studies on the Active Compounds of Alisma plantago - aquatica"

- "Quality Assurance in Herbal Extract Production: The Case of Alisma plantago - aquatica"

- "Market Analysis of Herbal Extracts: Focus on Alisma plantago - aquatica"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Elderberry Extract

2024-12-10

-

Artichoke Extract

2024-12-10

-

Curcuma Longa Extract/Turmeric extract

2024-12-10

-

Golden Seal Extract

2024-12-10

-

Lily extract

2024-12-10

-

Resveratrol extract

2024-12-10

-

Yellow Pine Extract

2024-12-10

-

Acai Berry Extract

2024-12-10

-

Reishi mushroom extract

2024-12-10

-

Camu Camu Extract

2024-12-10