- 0086-571-85302990

- sales@greenskybio.com

Tamarind extract powder products: Which extraction technologies should your enterprise invest in?

2024-12-10

Introduction

For enterprises aiming to enter the Tamarind extract powder market, the choice of extraction technology is a critical decision that can significantly impact the success of their business operations. Tamarind extract powder has a wide range of applications in the food, pharmaceutical, and cosmetic industries. Different extraction technologies offer various advantages and disadvantages in terms of economy, productivity, and quality control. This article will comprehensively analyze several extraction technologies to help enterprises make informed investment decisions.

Maceration Extraction

How it Works

Maceration extraction is one of the most traditional methods used for extracting Tamarind extract powder. In this process, tamarind is soaked in a solvent, usually water or an organic solvent, over an extended period. The solvent gradually penetrates the tamarind tissues, dissolving the desired components such as polysaccharides, acids, and flavonoids. As time passes, the concentration of these components in the solvent increases.

Advantages

- Cost - friendly for small - scale operations: The equipment required for maceration extraction is relatively simple and inexpensive. Small - scale enterprises can start with basic glassware or plastic containers, making it an accessible option for those with limited capital.

- Low - tech requirement: This method does not demand highly sophisticated technical knowledge or complex machinery. It can be easily carried out by operators with basic training, reducing the need for extensive technical support.

Disadvantages

- Time - consuming: Maceration extraction can take a long time, sometimes several days or even weeks, depending on the nature of the tamarind sample and the desired extraction efficiency. This long extraction time can limit the productivity of the enterprise, especially when there is a high demand for the product.

- Lower extraction yield: Compared to some modern extraction methods, maceration extraction may not be able to extract all the valuable components from the tamarind. Some components may remain trapped in the plant matrix, resulting in a relatively lower overall extraction yield.

Pressurized Liquid Extraction

How it Works

Pressurized liquid extraction (PLE) operates under high temperatures and pressures. The increased temperature and pressure enhance the solubility of the components within the tamarind. By subjecting the tamarind - solvent mixture to these extreme conditions, the solvent can more effectively penetrate the cell walls of the tamarind and dissolve a greater amount of the desired compounds.

Advantages

- Higher extraction yields: The combination of high temperature and pressure allows for a more thorough extraction of components from the tamarind. This can result in significantly higher yields compared to maceration extraction, ensuring that more of the valuable substances are recovered.

- Shorter extraction time: PLE can complete the extraction process in a relatively short time, typically within a few hours. This is a major advantage for enterprises that need to produce large quantities of tamarind extract powder within a limited time frame.

Disadvantages

- High equipment cost: The equipment used for pressurized liquid extraction is complex and expensive. It requires high - pressure vessels, precise temperature control systems, and safety mechanisms to ensure the operation is carried out safely. This high initial investment can be a significant barrier for small and medium - sized enterprises.

- Strict safety requirements: Due to the high - pressure and high - temperature conditions involved, there are strict safety regulations that need to be followed. Any malfunction in the equipment can lead to serious safety hazards, such as explosions or the release of harmful substances. This requires well - trained operators and regular equipment maintenance.

Membrane - Based Extraction Technology

How it Works

Membrane - based extraction technology utilizes semi - permeable membranes to selectively separate components. In the case of tamarind extract powder production, the membrane allows the passage of certain components while blocking others. For example, it can separate impurities from the desired extract, resulting in a purer final product.

Advantages

- High - quality product: The selective separation ability of the membrane - based technology ensures that the tamarind extract powder obtained is of high purity. This is highly desirable in industries such as pharmaceuticals and cosmetics where product quality and purity are of utmost importance.

- Environmentally friendly: This technology often uses less solvent compared to other extraction methods, reducing the environmental impact associated with solvent disposal.

Disadvantages

- Membrane fouling: One of the main challenges in membrane - based extraction is membrane fouling. Over time, impurities can accumulate on the membrane surface, reducing its efficiency. Regular membrane cleaning or replacement is required, which can add to the operating costs.

- Lower extraction rate: In some cases, the extraction rate of membrane - based extraction may be lower compared to pressurized liquid extraction. This means that it may take longer to obtain a sufficient amount of the extract, which could affect production schedules.

Weighing the Options

Economy

- For small - scale enterprises with limited budgets, maceration extraction may be the most cost - effective option initially. However, in the long run, if the enterprise aims to scale up production, the lower extraction yield and longer extraction time may lead to higher overall costs. Pressurized liquid extraction has a high initial investment in equipment but can offer higher productivity in terms of extraction yield and time, which may be more cost - effective for large - scale production. Membrane - based extraction technology has relatively lower solvent costs and can produce high - quality products, but the costs associated with membrane maintenance need to be considered.

Productivity

- Pressurized liquid extraction offers the highest productivity in terms of extraction time, being able to produce large quantities of extract in a short period. Maceration extraction has the lowest productivity due to its long extraction time. Membrane - based extraction technology may have a relatively lower productivity compared to pressurized liquid extraction, especially if membrane fouling occurs frequently.

Quality Control

- Membrane - based extraction technology provides the best quality control as it can produce a purer product. Pressurized liquid extraction can also maintain a relatively high quality if the process parameters are carefully controlled. Maceration extraction may have more variability in product quality due to the less - controlled extraction process.

Conclusion

Enterprises considering investment in tamarind extract powder production need to carefully evaluate the different extraction technologies available. Each technology has its own set of advantages and disadvantages in terms of economy, productivity, and quality control. Maceration extraction is suitable for small - scale and budget - constrained operations, while pressurized liquid extraction is more appropriate for large - scale production with a focus on high productivity. Membrane - based extraction technology is an excellent choice for enterprises that prioritize product quality and environmental sustainability. By thoroughly understanding these technologies and their implications, enterprises can make a strategic investment decision that aligns with their business goals and long - term development.

FAQ:

Q1: What are the main extraction technologies for tamarind extract powder?

There are mainly three extraction technologies for tamarind extract powder. The first one is maceration extraction, which soaks tamarind in a solvent over time. The second is pressurized liquid extraction that operates at high temperatures and pressures. And the third is the emerging membrane - based extraction technology.

Q2: Which extraction technology is the most cost - effective for small - scale enterprises?

For small - scale enterprises, maceration extraction can be a cost - friendly option. Although it is time - consuming, it doesn't require complex equipment and high - cost operation processes, so it may be more suitable in terms of cost - effectiveness.

Q3: What are the advantages of pressurized liquid extraction?

The advantage of pressurized liquid extraction is that it can operate at high temperatures and pressures. This can increase the solubility of components, which in turn results in higher extraction yields.

Q4: What makes membrane - based extraction technology special?

Membrane - based extraction technology is special because it has the advantage of selectively separating components. This can lead to a purer tamarind extract powder compared to other extraction methods.

Q5: What factors should enterprises consider when choosing an extraction technology?

Enterprises should consider factors such as economy, productivity, and quality control when choosing an extraction technology. Economy includes the cost of equipment, operation, and raw materials. Productivity refers to the extraction yield and speed. Quality control is related to the purity and quality of the final tamarind extract powder product.

Q6: How can enterprises ensure the safety of pressurized liquid extraction?

To ensure the safety of pressurized liquid extraction, enterprises need to establish strict safety measures. This includes using proper pressure - resistant equipment, having regular inspections and maintenance, and training employees on safety procedures to prevent potential accidents caused by high temperatures and pressures.

Related literature

- Advances in Tamarind Extraction Technologies"

- "Comparative Study of Tamarind Extraction Methods for Industrial Applications"

- "The Future of Tamarind Extract Powder Production: A Review of Extraction Technologies"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Tinospora cordifolia extract

2024-12-10

-

Panax Ginseng Leaf Extract

2024-12-10

-

Sophora Flavescens Root Extract

2024-12-10

-

Calendula Extract

2024-12-10

-

Kidney Bean Extract

2024-12-10

-

Senna Leaf Extract

2024-12-10

-

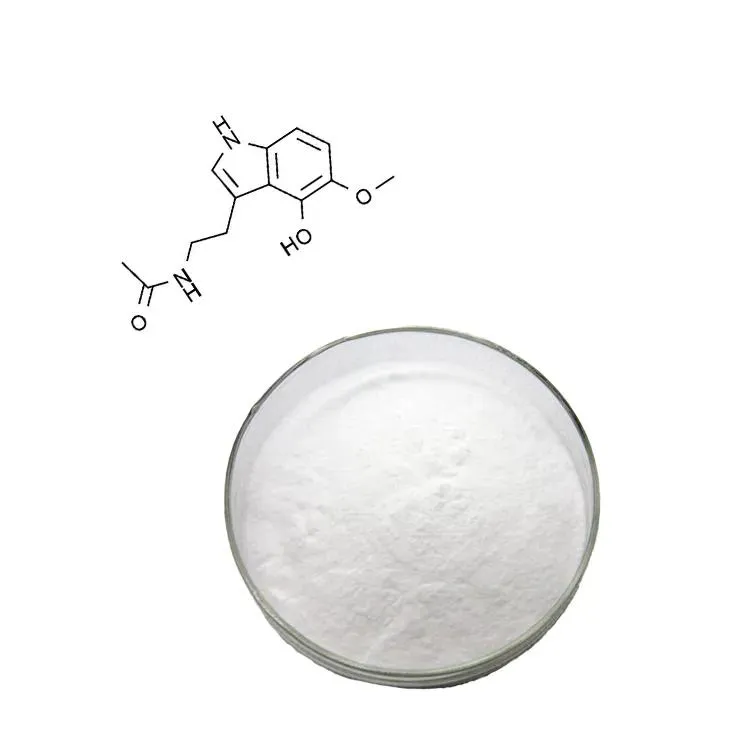

melatonin extract

2024-12-10

-

Yam Extract

2024-12-10

-

Purple Sweet Potato Extract

2024-12-10

-

Agaricus Blazei Extract

2024-12-10