- 0086-571-85302990

- sales@greenskybio.com

Only cooperate with the best contract manufacturers of Phellodendron amurense extract.

2024-12-10

1. Introduction

Phellodendron amurense extract has been gaining significant attention in various industries, such as the pharmaceutical, cosmetic, and food supplement sectors. Its unique properties make it a valuable ingredient. However, when it comes to its production, working with the best contract manufacturer is not a matter of choice but a necessity. This article will explore the reasons behind this and analyze the key factors that distinguish the top contract manufacturers in this field.

2. The Significance of Environmental Sustainability in the Manufacturing Process

2.1. Resource Conservation

The best contract manufacturers of Phellodendron amurense extract understand the importance of conserving natural resources. They ensure that the raw materials, in this case, Phellodendron amurense, are sourced sustainably. This means that they may work with suppliers who follow ethical harvesting practices, such as not over - exploiting the natural habitats of the plant. For example, they might encourage the use of selective harvesting methods that allow the plant to regenerate over time. By doing so, they not only protect the environment but also ensure the long - term availability of the raw material for their production.

2.2. Waste Management

Efficient waste management is another crucial aspect of environmental sustainability. Top - notch contract manufacturers have proper systems in place to handle waste generated during the extraction process. This includes both solid and liquid waste. They may use advanced technologies to treat and recycle waste water, reducing the environmental impact of their operations. For solid waste, they could explore options like composting or repurposing, instead of simply disposing it in landfills. By minimizing waste, they contribute to a cleaner and more sustainable environment.

2.3. Energy Efficiency

These manufacturers also focus on energy - efficient production processes. They might invest in modern equipment that consumes less energy while still maintaining high - quality extraction. For instance, some may use energy - saving extraction machines that are designed to optimize the use of heat or electricity. This not only reduces their production costs but also helps in reducing the overall carbon footprint associated with the manufacturing of Phellodendron amurense extract.

3. Innovation in Product Formulation

3.1. Research and Development

The leading contract manufacturers in this area are constantly engaged in research and development (R & D). They strive to discover new and improved ways of formulating Phellodendron amurense extract. This could involve exploring different extraction methods to enhance the purity and potency of the extract. For example, they might be researching on supercritical fluid extraction, which can produce a higher - quality extract compared to traditional methods. Through continuous R & D, they can offer products that are more effective and have a wider range of applications.

3.2. Customization

Another aspect of innovation is the ability to customize the product formulation. Different clients may have different requirements depending on their end - use applications. A good contract manufacturer can tailor - make the Phellodendron amurense extract to meet specific needs. For instance, in the cosmetic industry, clients may need an extract with a particular texture or solubility for use in creams or lotions. The best manufacturers can adjust the formulation accordingly, adding appropriate additives or modifying the extraction process to achieve the desired product characteristics.

3.3. Compatibility with Other Ingredients

Innovation also extends to ensuring the compatibility of Phellodendron amurense extract with other ingredients. In the pharmaceutical or food supplement sectors, the extract often needs to be combined with other active ingredients or additives. The top contract manufacturers conduct studies to ensure that there are no adverse interactions between the Phellodendron amurense extract and other components. This allows for the creation of more complex and effective formulations.

4. Customer Service Quality

4.1. Communication

Effective communication is a cornerstone of excellent customer service. The best contract manufacturers maintain clear and open lines of communication with their clients. They promptly respond to inquiries, whether it is about the production process, product specifications, or delivery schedules. This helps in building trust and ensuring that the client is well - informed throughout the project. For example, if a client has a question about the quality control measures for Phellodendron amurense extract, the manufacturer should be able to provide detailed and accurate answers in a timely manner.

4.2. Flexibility

Customer needs can change during the course of a project, and the top contract manufacturers are flexible enough to adapt. They can adjust production volumes, change product formulations within reason, or modify delivery schedules according to the client's requirements. This flexibility is especially important in the fast - paced industries where Phellodendron amurense extract is used, such as the cosmetics and food supplement industries where trends can change quickly.

4.3. After - Sales Support

Good after - sales support is also a sign of high - quality customer service. The best contract manufacturers offer assistance even after the product has been delivered. This could include providing technical support if the client encounters any issues with using the Phellodendron amurense extract in their products. They may also be open to feedback and use it to improve their future production processes or product formulations.

5. Key Elements that Make a Contract Manufacturer Stand Out

5.1. Quality Control

Stringent quality control measures are essential for a contract manufacturer of Phellodendron amurense extract. They should have a comprehensive quality management system in place that monitors every step of the production process. This includes testing the raw materials for purity and authenticity, as well as conducting in - process and final product quality checks. For example, they may use advanced analytical techniques like high - performance liquid chromatography (HPLC) to ensure that the extract meets the required quality standards. Quality control also extends to packaging, ensuring that the product is properly packaged to maintain its stability and quality during storage and transportation.

5.2. Regulatory Compliance

Compliance with relevant regulations is another key factor. The manufacturing of Phellodendron amurense extract is subject to various regulations depending on its end - use. For example, in the pharmaceutical industry, it must meet strict drug manufacturing regulations, while in the cosmetic industry, it needs to comply with cosmetic ingredient regulations. The best contract manufacturers stay up - to - date with these regulations and ensure that their production processes and products are fully compliant. This not only protects the clients from potential legal issues but also safeguards the reputation of the manufacturer.

5.3. Experience and Expertise

Years of experience in the production of Phellodendron amurense extract can give a contract manufacturer a significant edge. Experienced manufacturers are more likely to have encountered and overcome various production challenges. They have in - depth knowledge of the plant's properties, extraction techniques, and product formulation. Their expertise allows them to produce high - quality extracts consistently and troubleshoot any issues that may arise during production more effectively.

6. Why It's Essential to Choose Only the Best for Phellodendron amurense Extract

6.1. Product Quality and Efficacy

The best contract manufacturers are more likely to produce Phellodendron amurense extract of high quality and efficacy. This is crucial for industries that rely on the extract for its medicinal, cosmetic, or nutritional properties. High - quality extract can ensure better results in applications such as treating certain diseases in the pharmaceutical field, enhancing skin health in cosmetics, or providing nutritional benefits in food supplements.

6.2. Reputation and Brand Image

Partnering with a top - notch contract manufacturer can enhance the reputation and brand image of the client. When a company uses a high - quality extract produced by a well - known and respected manufacturer, it sends a positive signal to consumers. This can lead to increased consumer trust and loyalty, which are essential for the success of any product in the market.

6.3. Long - Term Business Viability

Choosing the best contract manufacturer also contributes to the long - term viability of the client's business. A reliable manufacturer can ensure a stable supply of high - quality Phellodendron amurense extract, which is important for maintaining product consistency. In addition, they can adapt to changes in the market and regulatory environment, helping the client's business to stay competitive and sustainable in the long run.

7. Conclusion

In conclusion, when it comes to Phellodendron amurense extract, working with the best contract manufacturer is of utmost importance. The significance of environmental sustainability, innovation in product formulation, and high - quality customer service cannot be overstated. The key elements that make a contract manufacturer stand out, such as quality control, regulatory compliance, and experience, further emphasize the need to choose only the best. By doing so, companies can ensure high - quality products, enhance their reputation, and secure their long - term business viability.

FAQ:

What are the criteria for determining the best contract manufacturer of Phellodendron amurense extract?

The criteria include strict quality control measures in the extraction process to ensure the purity and potency of the Phellodendron amurense extract. Advanced manufacturing technology is also crucial as it can affect the efficiency and consistency of production. Additionally, a good contract manufacturer should have a solid reputation in the industry, which can be reflected in positive customer reviews and long - term business partnerships. Environmental compliance is another factor, such as proper waste management during the manufacturing process.

How does environmental sustainability in the manufacturing process of Phellodendron amurense extract relate to choosing the best contract manufacturer?

Environmental sustainability is a significant aspect. A top - notch contract manufacturer will implement sustainable practices like using renewable energy sources in the extraction and production facilities. They will also have proper waste disposal systems to minimize environmental impact. This not only shows their corporate social responsibility but also indicates their long - term viability and quality management. For example, a manufacturer that recycles water used in the extraction process is more likely to be detail - oriented and efficient in all aspects of production, which are desirable traits for producing high - quality Phellodendron amurense extract.

Why is innovation in product formulation important when it comes to Phellodendron amurense extract contract manufacturers?

Innovation in product formulation can lead to better - performing Phellodendron amurense extract products. A good contract manufacturer will invest in research and development to find new ways to enhance the bioavailability or stability of the extract. This can open up new market opportunities and meet the evolving needs of customers. For instance, they may develop unique encapsulation techniques that protect the extract from degradation and improve its absorption in the body, giving their products a competitive edge.

How can the quality of customer service influence the choice of a contract manufacturer for Phellodendron amurense extract?

High - quality customer service is essential. A reliable contract manufacturer will provide timely communication, be responsive to clients' inquiries and concerns, and offer after - sales support. For example, if there are any issues with the product quality or delivery, they should be able to resolve them quickly. Good customer service also implies that they are transparent in their operations, sharing information about the manufacturing process and quality control measures with their clients, which builds trust and is crucial when choosing a contract manufacturer for Phellodendron amurense extract.

What risks are associated with not choosing the best contract manufacturer for Phellodendron amurense extract?

There are several risks. Sub - par quality control may lead to inconsistent or impure extracts, which can affect the efficacy and safety of the final product. Poor manufacturing practices might also result in production delays or supply chain disruptions. Additionally, a manufacturer with a bad environmental record may face regulatory issues, which could in turn impact the clients associated with them. Lack of innovation may mean that the product becomes obsolete in the market compared to competitors' offerings.

Related literature

- Title: Quality Assurance in Botanical Extract Manufacturing: The Case of Phellodendron amurense"

- Title: "Sustainable Practices in Extract Production: Focus on Phellodendron amurense"

- Title: "Innovation in Herbal Extract Formulation: Phellodendron amurense as an Example"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Sophora Japonica Flower Extract

2024-12-10

-

Cat Claw Extract

2024-12-10

-

Rosemary extract

2024-12-10

-

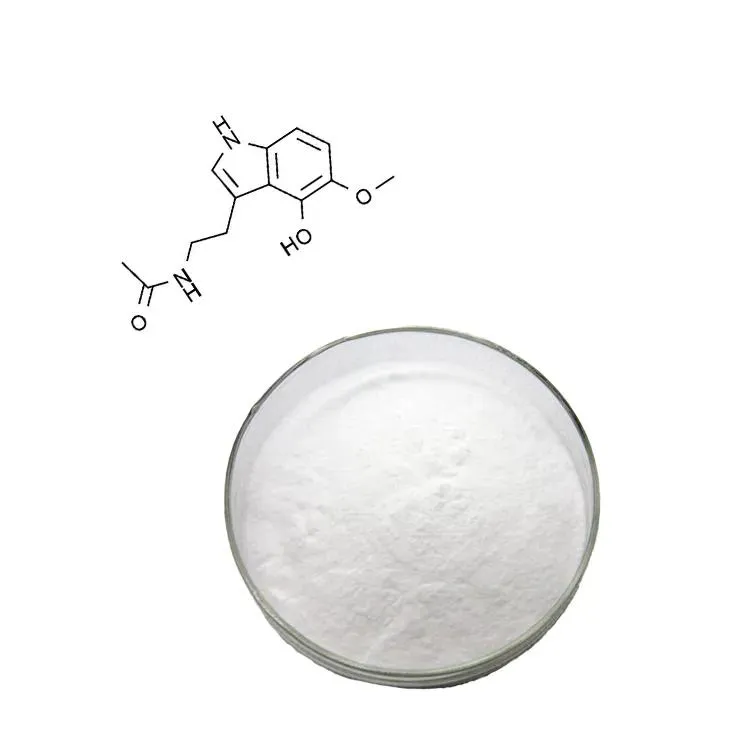

melatonin extract

2024-12-10

-

Bitter Melon Extract

2024-12-10

-

Red Vine Extract

2024-12-10

-

Alisma Extract

2024-12-10

-

Peppermint Extract Powder

2024-12-10

-

Mango flavored powder

2024-12-10

-

Uridine-5'-monophosphate Disodium salt

2024-12-10