- 0086-571-85302990

- sales@greenskybio.com

Only cooperate with the best contract manufacturers of milk thistle extract.

2024-12-10

Introduction

Milk Thistle Extract has been widely recognized for its various health benefits, which has led to its increasing use in different products such as dietary supplements, herbal remedies, and some functional foods. As a result, when it comes to the production of products containing Milk Thistle Extract, choosing the right contract manufacturer is of utmost importance. Only partnering with the best contract manufacturer can ensure that the final products are of high quality, compliant with regulations, and effective in delivering the expected health benefits.

Quality of Raw Materials

The first and crucial aspect to consider when evaluating a contract manufacturer for Milk Thistle Extract is the quality of the raw materials they use.

Source of Milk Thistle

A top - notch contract manufacturer should be very particular about the source of milk thistle. They should source it from regions known for producing high - quality milk thistle plants.

- Some regions may have better soil conditions, which can result in milk thistle plants with higher levels of active ingredients such as silymarin.

- Proper climate also plays a role. For example, areas with a suitable amount of sunlight and rainfall are more likely to yield healthy milk thistle plants.

Raw Material Testing

Before using the milk thistle in the production process, comprehensive testing of the raw materials is essential.

- The contract manufacturer should test for contaminants such as pesticides, heavy metals, and microbial contaminants.

- They also need to verify the potency of the active ingredients. For example, determining the silymarin content accurately to ensure that it meets the required standards for effective product formulation.

Quality Control Measures

Quality control is a cornerstone in the production process of milk thistle extract - based products by contract manufacturers.

In - Process Quality Control

During the extraction and production process, strict quality control should be in place.

- Monitoring of extraction parameters: For example, controlling the temperature, pressure, and solvent used in the extraction of milk thistle extract. Incorrect extraction conditions can lead to a lower yield of active ingredients or the formation of unwanted by - products.

- Regular sampling and testing: Samples should be taken at different stages of the production process to check for consistency in quality. This includes testing for the purity of the extract, the presence of any impurities, and the stability of the active ingredients.

Final Product Quality Control

Before the product is released to the market, the final product must pass rigorous quality control checks.

- Identity testing: Ensuring that the product is indeed milk thistle extract - based and contains the expected active ingredients. This can be done through various analytical techniques such as chromatography.

- Potency testing: Verifying that the product contains the appropriate amount of active ingredients to deliver the claimed health benefits. For example, a dietary supplement containing milk thistle extract should have a clearly defined and consistent silymarin content.

- Stability testing: Determining how the product will fare over time under different storage conditions. This helps in setting appropriate expiration dates and storage instructions.

Production Capabilities

The production capabilities of a contract manufacturer play a significant role in determining their suitability for handling milk thistle extract production.

Scale of Production

Different clients may have different volume requirements, and a good contract manufacturer should be able to accommodate a wide range of production scales.

- For small - scale start - up companies, the contract manufacturer should be able to produce relatively small batches efficiently without sacrificing quality. This allows start - ups to test the market with their milk thistle - based products.

- On the other hand, for larger companies with high - volume demands, the contract manufacturer should have the capacity to produce large quantities of products in a timely manner. This may involve having larger production facilities, more advanced equipment, and an efficient production line.

Flexibility in Formulation

Milk thistle extract can be used in different product formulations, and a top contract manufacturer should be able to offer flexibility in this regard.

- They should be able to produce various forms of products such as capsules, tablets, tinctures, or powders containing milk thistle extract. Each form may require different production techniques and equipment.

- Moreover, they should be able to adjust the formulation based on the specific requirements of the client. For example, adding other complementary ingredients to enhance the efficacy of the milk thistle extract in a particular product.

Regulatory Compliance

Given the nature of products containing milk thistle extract, regulatory compliance is non - negotiable for contract manufacturers.

Food and Drug Regulations

Depending on the country or region, there are specific food and drug regulations that govern the production and marketing of products containing milk thistle extract.

- The contract manufacturer should be well - versed in these regulations. For example, in the United States, dietary supplements containing milk thistle extract are regulated by the Food and Drug Administration (FDA). The manufacturer needs to comply with FDA's Good Manufacturing Practice (GMP) regulations.

- They should also be able to keep up with any changes in the regulations. Regulatory requirements may change over time, and the contract manufacturer should have a system in place to ensure timely compliance.

International Standards

If the products are intended for international markets, compliance with international standards is also crucial.

- Standards such as those set by the International Organization for Standardization (ISO) may be relevant. ISO certifications can be an indication of a contract manufacturer's commitment to quality and compliance on an international level.

- Compliance with international regulations also helps in ensuring that the products can be exported and sold in different countries without facing regulatory hurdles.

Research and Development

A forward - looking contract manufacturer should have a strong focus on research and development (R&D) in relation to milk thistle extract.

New Product Development

Constant innovation in product development can give clients a competitive edge in the market.

- The contract manufacturer should be able to develop new products based on milk thistle extract. For example, creating novel formulations that combine milk thistle extract with other trendy ingredients to target specific health concerns.

- They can also explore different delivery systems for milk thistle extract. For instance, developing a slow - release formulation that can provide a more sustained release of the active ingredients in the body.

Improving Extraction Techniques

Research into improving extraction techniques can lead to higher quality and more cost - effective production.

- By exploring new extraction methods, the contract manufacturer may be able to increase the yield of active ingredients from milk thistle. This can reduce the cost of raw materials per unit of final product.

- New extraction techniques may also result in a purer extract with fewer impurities, which can enhance the overall quality of the product.

Customer Service

Good customer service is an important aspect of a contract manufacturer's offering, especially when it comes to handling milk thistle extract production.

Communication

Effective communication between the contract manufacturer and the client is essential.

- The manufacturer should be responsive to the client's inquiries. Whether it's about the production process, quality control measures, or regulatory compliance, they should be able to provide timely and accurate answers.

- They should also keep the client informed about the progress of the production. For example, providing regular updates on the production schedule, any potential delays, and solutions to any issues that may arise during production.

Technical Support

Providing technical support to clients can enhance the overall value of the contract manufacturing service.

- If the client has specific requirements regarding the formulation or production of their milk thistle - based product, the contract manufacturer should be able to offer technical advice. For example, suggesting the best way to incorporate milk thistle extract into a particular product type.

- They can also assist the client in troubleshooting any problems that may occur during product development or production. This can help the client save time and resources.

Conclusion

When considering a contract manufacturer for milk thistle extract - based products, multiple factors need to be carefully evaluated. Quality of raw materials, quality control measures, production capabilities, regulatory compliance, research and development, and customer service all contribute to making a contract manufacturer stand out in this field.

By choosing the best contract manufacturer, companies can ensure that their products containing milk thistle extract are of high quality, compliant with regulations, and effective in providing the expected health benefits. This not only protects the reputation of the companies but also helps in building consumer trust in products containing this valuable extract.

FAQ:

What are the key quality control measures for a contract manufacturer of milk thistle extract?

Quality control measures for a contract manufacturer of milk thistle extract include strict sourcing of raw materials. They should ensure that the milk thistle is of high - quality, free from contaminants and pesticides. Laboratory testing at multiple stages, such as raw material inspection, in - process testing, and final product testing, is crucial. This helps in verifying the potency and purity of the extract. Additionally, compliance with relevant industry standards and regulations, like Good Manufacturing Practice (GMP), is a key quality control aspect.

How can one assess the production capabilities of a milk thistle extract contract manufacturer?

To assess the production capabilities of a milk thistle extract contract manufacturer, one can look at factors such as the scale of their production facilities. A larger facility may be able to handle higher volumes. Their equipment and technology play a role; modern and well - maintained extraction and processing equipment can ensure efficient and high - quality production. Also, the manufacturer's ability to scale up production according to demand is important. Their experience in handling similar products and the availability of skilled labor in their production process are also aspects to consider.

What regulatory compliance should a good milk thistle extract contract manufacturer meet?

A good milk thistle extract contract manufacturer should meet various regulatory compliance requirements. Firstly, they should comply with food and drug regulations depending on the intended use of the extract (e.g., if it is for dietary supplements or pharmaceuticals). This includes proper labeling requirements, safety standards, and purity regulations. They should also adhere to environmental regulations regarding waste management and sustainable sourcing. In addition, compliance with international quality standards like ISO certifications can also be an indication of a reliable contract manufacturer.

How does a contract manufacturer ensure the efficacy of milk thistle extract in the final product?

A contract manufacturer ensures the efficacy of milk thistle extract in the final product through proper extraction methods. Using the right solvents and extraction techniques can preserve the active compounds in the extract. They also need to ensure accurate dosing and formulation in the product. Stability testing is important to make sure that the extract remains effective over the product's shelf - life. Additionally, research and development efforts may be involved to optimize the product formulation for maximum efficacy.

What are the advantages of partnering with the best milk thistle extract contract manufacturer?

The advantages of partnering with the best milk thistle extract contract manufacturer are numerous. Firstly, product quality is ensured, which is crucial for consumer satisfaction and brand reputation. They can provide expertise in formulating products with milk thistle extract, leading to more effective and marketable products. Compliance with regulations reduces the risk of legal issues. The best manufacturers also often have better supply chain management, ensuring a stable supply of the extract. Moreover, they may offer cost - effective solutions due to their efficiency in production and sourcing.

Related literature

- Milk Thistle Extract: Production and Quality Assurance"

- "The Role of Contract Manufacturers in the Milk Thistle Extract Industry"

- "Quality Standards for Milk Thistle Extract in Contract Manufacturing"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

White mustard seed extract

2024-12-10

-

Bamboo Leaf extract

2024-12-10

-

American Ginseng Root Extract

2024-12-10

-

Angelica sinensis extract

2024-12-10

-

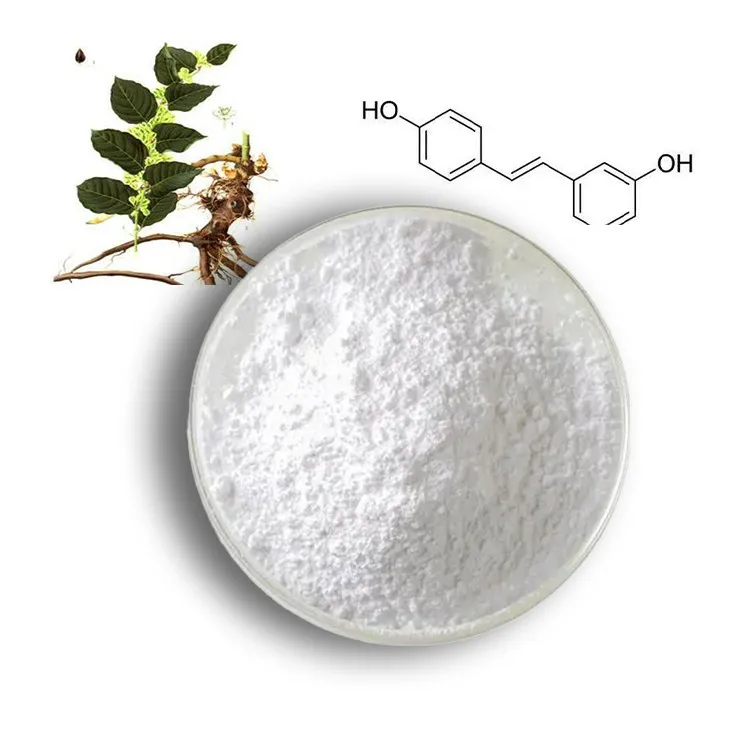

Resveratrol extract

2024-12-10

-

Sea buckthorn Juice Powder

2024-12-10

-

Hops Extract

2024-12-10

-

Troxerutin

2024-12-10

-

Hesperidin

2024-12-10

-

Beetroot Powder

2024-12-10