- 0086-571-85302990

- sales@greenskybio.com

Complete Guide to the Grinding Process of American Ginseng Root Extract: Step - by - Step Key Points

2024-12-18

1. Introduction

American Ginseng Root Extract has been highly valued in traditional medicine for its various health - promoting properties. The grinding process is a crucial step in preparing high - quality extract. This guide aims to provide a comprehensive understanding of the grinding process, from the initial selection of materials to the final quality control.

2. Equipment Selection

2.1 Grinding Machines

There are several types of grinding machines suitable for American Ginseng Root Extract. Mortar and Pestle: This is a traditional and simple option, especially suitable for small - scale or home - based grinding. It allows for a more manual control over the grinding process, but it can be time - consuming. Electric Grinders: These are more efficient and can handle larger quantities. They come in different models, such as blade grinders and burr grinders. Blade grinders are more common and cost - effective, but burr grinders can provide a more consistent grind size.

2.2 Additional Equipment

Sifting Tools: After grinding, sifting is necessary to separate the fine powder from any larger particles. A fine - mesh sieve can be used for this purpose. Containers: High - quality, airtight containers are required to store the ground extract. Glass jars are a good option as they do not react with the extract and can keep it fresh for a longer time.

3. Preparation of American Ginseng Root

3.1 Harvesting and Selection

The quality of the American ginseng root starts with proper harvesting. Roots should be harvested at the appropriate time, usually when they have reached a certain maturity level. During selection, look for roots that are healthy, free from diseases and pests, and have a good shape and size. Inspect for Damage: Any damaged or rotten parts should be removed as they can affect the quality of the extract.

3.2 Cleaning

Thorough cleaning is essential. Washing: Gently wash the roots with clean water to remove any dirt, soil, or debris. Avoid using harsh chemicals or excessive scrubbing as this may damage the root surface. Drying: After washing, allow the roots to dry completely. This can be done in a well - ventilated area, away from direct sunlight. Drying helps to reduce the moisture content, which is important for the grinding process.

4. Grinding Process

4.1 Coarse Grinding

- Start with the appropriate grinding machine. If using a mortar and pestle, place the dried American ginseng root in the mortar.

- Apply gentle pressure and start grinding in a circular motion. If using an electric grinder, set it to a low - speed setting for the initial coarse grinding.

- The goal of this step is to break the root into smaller pieces, but not necessarily into a fine powder. This can take some time, especially when using traditional methods.

4.2 Fine Grinding

- Once the root has been coarsely ground, increase the intensity of the grinding. For electric grinders, you can increase the speed.

- Continue grinding until the desired fineness is achieved. This can be determined by periodically checking the texture of the ground material. A finer grind is usually preferred for better extraction efficiency.

- Be careful not to over - grind, as this may cause the extract to become too fine and potentially affect its quality.

5. Sifting

- After grinding, transfer the ground American Ginseng Root Extract to a sifting device, such as a fine - mesh sieve.

- Gently shake the sieve to allow the fine powder to pass through while retaining any larger particles.

- The larger particles can be collected and re - ground if necessary to ensure maximum utilization of the root material.

6. Quality Control

6.1 Particle Size Analysis

Use appropriate tools, such as a microscope or a particle size analyzer, to check the particle size distribution of the ground extract. Ideal Particle Size: The ideal particle size should be within a certain range to ensure optimal extraction. If the particles are too large, the surface area available for extraction may be limited. If they are too small, it may lead to issues such as clumping.

6.2 Purity Testing

- Check for the presence of any impurities, such as dirt, other plant materials, or foreign substances.

- Methods such as visual inspection, chemical analysis, and spectroscopy can be used to ensure the purity of the extract.

6.3 Moisture Content Measurement

Excessive moisture can lead to spoilage and affect the stability of the extract. Moisture Analyzers: Use moisture analyzers to measure the moisture content of the ground extract. The moisture content should be within the acceptable range, typically less than a certain percentage.

7. Storage

- Once the ground American Ginseng Root Extract has passed quality control, it should be stored in an appropriate container. As mentioned before, glass jars are a good choice.

- Store the containers in a cool, dry place, away from direct sunlight and sources of heat. This helps to maintain the quality and potency of the extract over time.

- Label the containers clearly with information such as the date of grinding, the batch number, and any relevant quality control data.

8. Conclusion

The grinding process of American Ginseng Root Extract is a multi - step process that requires careful attention to detail. From equipment selection to quality control and storage, each step plays a vital role in producing a high - quality extract. By following this complete guide, both beginners and experienced practitioners can ensure the production of American Ginseng Root Extract with consistent quality and optimal properties.

FAQ:

What are the important factors to consider when selecting equipment for grinding American Ginseng root extract?

When selecting equipment for grinding American Ginseng root extract, several factors need to be considered. Firstly, the fineness of the grind required. Different applications may demand different levels of fineness, so the equipment should be able to achieve the desired particle size. Secondly, the capacity of the equipment. It should be able to handle the quantity of ginseng root extract to be ground within a reasonable time frame. Thirdly, the material of the equipment. Since American Ginseng root extract is a valuable and often used in the health - related field, the equipment should be made of non - reactive materials to avoid contamination. Fourthly, ease of cleaning and maintenance. This is important to ensure the hygiene and long - term performance of the equipment.

What are the common grinding techniques for American Ginseng root extract?

There are several common grinding techniques for American Ginseng root extract. One is the mechanical grinding method, which uses mills such as ball mills or hammer mills. Ball mills are often used for fine grinding, where the grinding media (balls) in the mill help to break down the ginseng root extract into smaller particles through continuous tumbling and impact. Hammer mills, on the other hand, use high - speed rotating hammers to smash the extract. Another technique is cryogenic grinding. This involves freezing the American Ginseng root extract before grinding. Freezing makes the material more brittle, which can result in a more efficient and finer grind. It also helps to preserve the bioactive components of the extract as the low temperature reduces the likelihood of chemical reactions during grinding.

How can quality control be ensured during the grinding process of American Ginseng root extract?

Quality control during the grinding process of American Ginseng root extract can be ensured in multiple ways. Firstly, regular inspection of the grinding equipment is necessary. This includes checking for wear and tear of the parts, as damaged parts can affect the quality of the grind. Secondly, monitoring the particle size distribution of the ground extract. This can be done using particle size analyzers. The particle size should be within the specified range for the intended use of the extract. Thirdly, ensuring the purity of the extract during grinding. This means preventing cross - contamination with other substances. The grinding environment should be clean, and the equipment should be properly cleaned between different batches. Fourthly, testing the bioactivity of the ground extract. Since American Ginseng has certain bioactive components, it is important to ensure that the grinding process does not significantly reduce their activity.

Are there any safety precautions to be taken during the grinding of American Ginseng root extract?

Yes, there are safety precautions to be taken during the grinding of American Ginseng root extract. When using mechanical grinding equipment, operators should be trained to use the machinery properly to avoid accidents such as getting fingers caught in moving parts. For cryogenic grinding, proper handling of the freezing agents is crucial to prevent frostbite. Also, since the grinding process may generate dust, appropriate ventilation systems should be in place to protect the operators from inhaling the dust. Additionally, if any additives or solvents are used during the grinding process, their proper handling and storage should be ensured to avoid potential hazards.

Can the grinding process affect the nutritional value of American Ginseng root extract?

The grinding process can potentially affect the nutritional value of American Ginseng root extract. If the grinding is too harsh or if the temperature and pressure conditions are not properly controlled, it can lead to the degradation of bioactive components. For example, excessive heat generated during grinding can cause some heat - sensitive nutrients or active compounds in the ginseng root extract to break down. However, if the grinding process is carefully optimized, such as using cryogenic grinding or appropriate grinding speeds and times, the impact on the nutritional value can be minimized.

Related literature

- Study on the Grinding Technology of American Ginseng Root"

- "Optimization of American Ginseng Root Extract Grinding Process for High - Quality Production"

- "The Influence of Grinding on the Bioactive Components of American Ginseng Root Extract"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

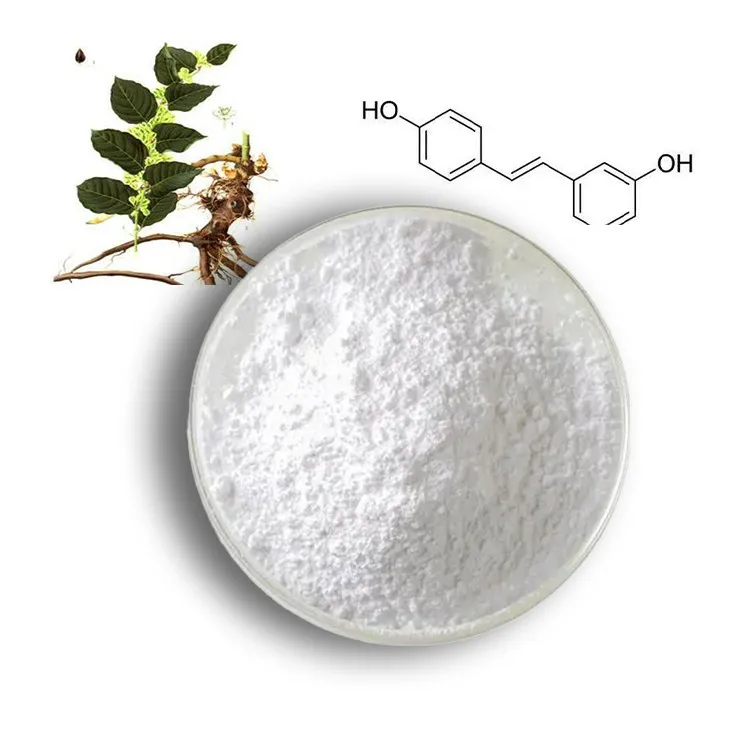

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Konjac Powder

2024-12-18

-

Kelp Extract Powder

2024-12-18

-

Natural grape seed extract

2024-12-18

-

Beetroot juice Powder

2024-12-18

-

Cactus Extract

2024-12-18

-

Coconut Water Powder

2024-12-18

-

Berberis aristata Extract

2024-12-18

-

Resveratrol extract

2024-12-18

-

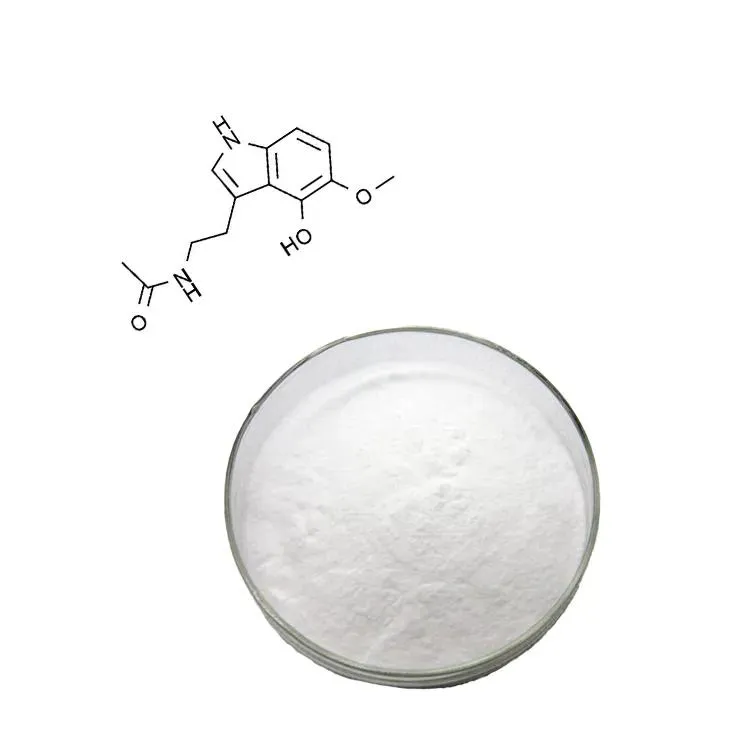

melatonin extract

2024-12-18

-

Green Tea Extract

2024-12-18