- 0571-85302990

- sales@greenskybio.com

Sodium Carboxymethyl Cellulose (CMC-Na) Ultimate Guide: Benefits, Applications, and Sourcing from a

2025-11-27

Sodium Carboxymethyl Cellulose (CMC-Na) Ultimate Guide: Benefits, Applications, and Sourcing from a Trusted Supplier

Meta Description: Explore the versatile benefits of Sodium Carboxymethyl Cellulose (CMC-Na, Food Grade, GB 1886.232) for food, pharmaceuticals, cosmetics & industry. Learn about its viscosity control, stability, and source premium CMC-Na from a reliable manufacturer. Request a FREE quote & sample today!

Introduction

Sodium Carboxymethyl Cellulose (CMC-Na), a water-soluble cellulose ether derivative, has become a "fundamental functional raw material" in the food, pharmaceutical, cosmetic, and industrial sectors, thanks to its natural origin, excellent water solubility, and versatility. Compared to traditional natural gums, CMC-Na offers superior advantages in viscosity regulation, system stability, and salt/pH resistance. It not only meets the formulation needs of clean-label foods but also complies with the strict regulatory standards for pharmaceutical excipients, making it an indispensable "all-round" raw material in modern industry.

Part 1: What is Sodium Carboxymethyl Cellulose (CMC-Na)?

Basic Information

• Raw Material Source: It uses natural cellulose as the core raw material, mainly derived from cotton linters (high-purity cellulose) or wood pulp. After chemical modification, it forms a water-soluble polymer that retains the safety of natural raw materials while gaining new functions.

• Production Process: The core process includes "Alkalization → Etherification → Neutralization → Purification → Drying → Crushing", specifically: 1) Cellulose reacts with sodium hydroxide to form alkali cellulose (alkalization); 2) Alkali cellulose reacts with sodium chloroacetate to introduce carboxymethyl ether groups (etherification, which determines the core performance of the product); 3) Excess alkali is neutralized with hydrochloric acid; 4) Salts and impurities are removed by washing (purification); 5) Low-temperature drying and graded crushing are performed to finally obtain powder products with different viscosity specifications.

• Active Components: The core functional group is the carboxymethyl ether group (-CH₂COONa), and its Degree of Substitution (DS) is a key indicator. DS refers to the number of hydroxyl groups substituted by carboxymethyl groups on each cellulose glucose unit, with a common range of 0.6-1.2. Higher DS results in stronger water solubility, salt resistance, and thickening ability, making it suitable for a wider range of scenarios.

• Standard Specification: The mainstream grade is Food Grade, complying with China National Standard GB 1886.232-2016 "National Food Safety Standard - Food Additive Sodium Carboxymethyl Cellulose" and EU Regulation (EU) No. 1129/2011. Its CAS number is 9004-32-4.

Part 2: Key Benefits and Mechanisms of Action

The functional advantages of CMC-Na stem from its unique structure of "linear polysaccharide chain + carboxymethyl ether group", with specific benefits and mechanisms as follows:

• Efficient Thickening and Rheology Regulation: CMC-Na molecular chains combine with water molecules through hydrogen bonds in aqueous solutions to form a three-dimensional network structure, which can quickly increase the system viscosity. Moreover, the viscosity is less affected by shear force (pseudoplastic fluid characteristics) — for example, viscosity decreases during stirring for easy processing, and recovers after standing to stabilize the product form, making it suitable for scenarios such as sauces and cosmetics that require "easy processing + stable texture".

• Emulsification and Suspension Stability: The hydrophilicity of carboxymethyl ether groups allows CMC-Na molecules to adsorb on the surface of oil droplets or solid particles, forming a charged protective film that reduces interfacial tension and prevents particle agglomeration or oil-water separation. For example, it can stabilize protein particles in plant-based milk and prevent active ingredients from settling in pesticide suspensions.

• Film-Forming and Adhesive Functions: When CMC-Na aqueous solution dries, it forms a transparent, flexible, and water-resistant film with breathability, suitable for food coatings (e.g., fruit preservation films), pharmaceutical coatings (e.g., enteric coatings for tablets), or industrial adhesives (e.g., paper coatings). As an adhesive, it can enhance the binding force between particles and improve the moldability of tablets and granules.

• Water Retention Capacity: A large number of carboxymethyl ether groups can form stable hydrogen bonds with water molecules to firmly lock in moisture — in baked goods, it can reduce moisture loss and extend shelf life; in skincare products, it can form a moisturizing film to enhance skin hydration.

• Wide Compatibility and Stability: It maintains stable performance in the pH range of 4.0-10.0 (precipitation occurs in overly acidic conditions), and high-DS grades can tolerate a certain amount of salt (e.g., salt in soy sauce and meat products). It does not react with common ingredients such as sweeteners, pigments, and preservatives, making it suitable for complex formulations.

Part 3: Wide-Ranging Application Industries

The versatility of CMC-Na covers multiple industries, with specific application scenarios as follows:

• Food and Beverage Industry: The core application field, accounting for over 60% — 1) Cold drinks (ice cream, popsicles): Thickens and inhibits ice crystal growth to improve texture smoothness; 2) Dairy products (yogurt, probiotic drinks): Stabilizes the system and prevents whey separation; 3) Beverages (fruit and vegetable juices, plant-based milk): Suspends pulp or protein particles to avoid stratification; 4) Baking (bread, cakes): Retains moisture, improves texture, and extends shelf life; 5) Sauces (ketchup, salad dressing): Regulates viscosity to ensure uniform texture and prevent oil-water separation; 6) Convenience foods (instant noodle seasoning packets): Acts as a thickener to enhance soup consistency.

• Pharmaceutical Formulation Field: As a pharmaceutical excipient (USP-NF grade) with high safety — 1) Oral formulations: Binder for tablets and capsules (improving moldability), suspending agent for oral suspensions (ensuring uniform dispersion of drug particles); 2) Topical formulations: Matrix for ointments and gels (regulating consistency and enhancing skin adhesion), thickener for eye drops (extending the residence time of drugs on the eye surface); 3) Intestinal administration: As a laxative ingredient, softens stool by increasing intestinal moisture.

• Cosmetics and Personal Care: Mild and non-irritating, suitable for sensitive skin — 1) Skincare products (creams, lotions, masks): Thickens and stabilizes, forms a moisturizing film, and improves skin feel; 2) Hair care products (shampoos, conditioners): Acts as a conditioner to improve hair combability and reduce frizz; 3) Oral care (toothpaste): Thickens and shapes, prevents solid particle sedimentation, and enhances smoothness during brushing.

• Industrial Field: 1) Detergents: Acts as an anti-redeposition agent to prevent dirt from reattaching to clothes and improve cleaning efficiency; 2) Textile industry: As a sizing agent to enhance yarn strength and reduce breakage during weaving; 3) Paper industry: As a coating agent to improve paper smoothness and printability; 4) Oil drilling: As a drilling fluid thickener to regulate drilling fluid viscosity, carry cuttings, and protect the wellbore.

• Agricultural Field: 1) Pesticides: As a stabilizer for suspensions to improve the dispersibility of active pesticide ingredients and enhance efficacy; 2) Fertilizers: As a coating agent to control fertilizer release rate, achieve slow-release effects, and reduce nutrient loss.

Part 4: How to Choose High-Quality CMC-Na?

The selection of high-quality CMC-Na should focus on "performance adaptability" and "compliance safety", with core criteria as follows:

• Clarify Core Parameter Requirements: Determine DS and viscosity based on product formulations — avoid performance failure due to parameter mismatch.

• Compliance Certifications: Prioritize products that meet the standards of the target market — food customers need to confirm GB 1886.232 standard, EU exports need to comply with EU No. 1129/2011, and pharmaceutical customers need to confirm USP-NF and EP certifications.

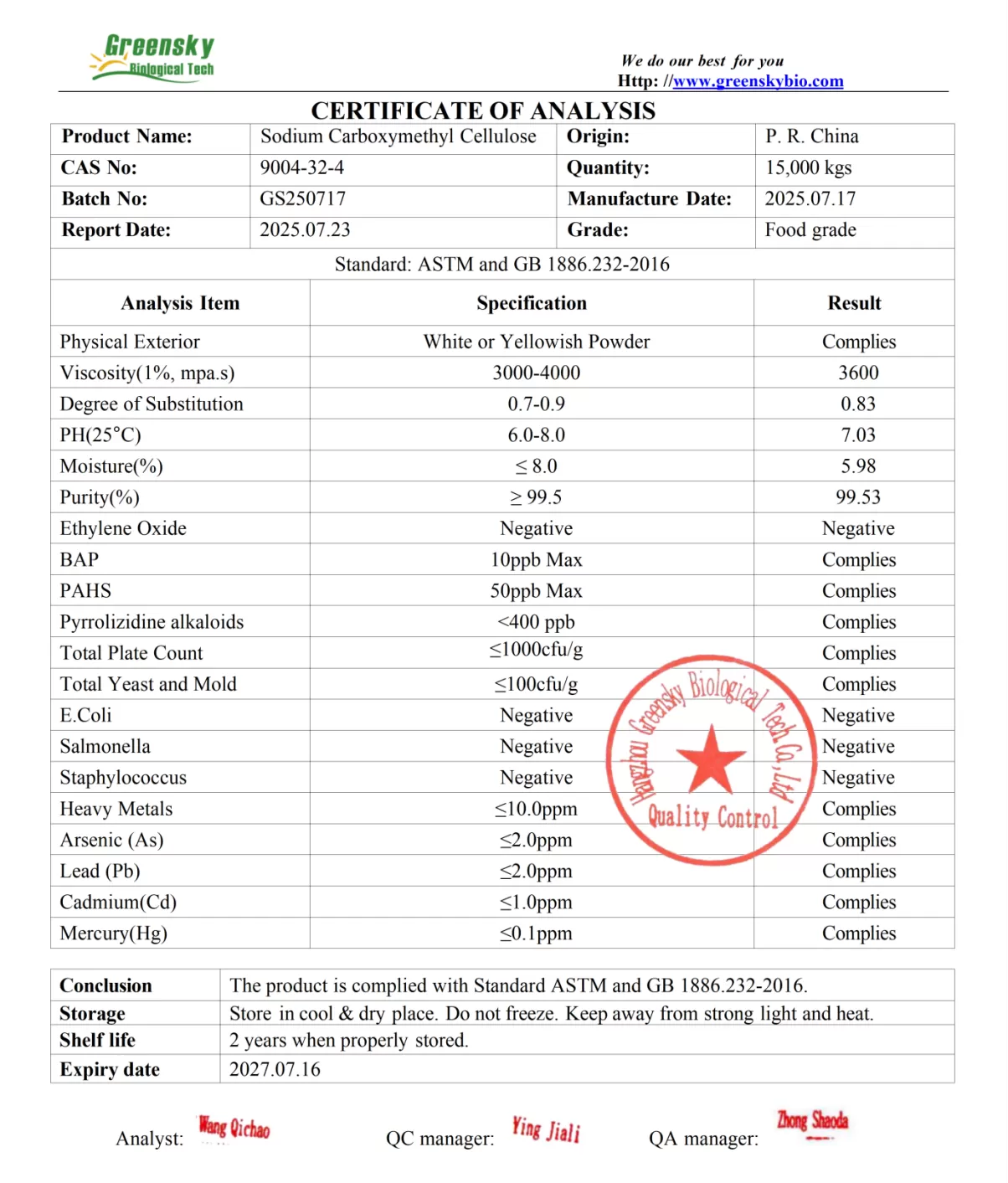

• Process and Purity: Ask the supplier whether "high-purity cellulose raw materials + multi-stage purification processes" are used — inferior raw materials or simplified purification can lead to residual impurities (e.g., salts, unreacted cellulose), affecting product taste (food) or safety (pharmaceuticals); confirm CMC content ≥99% and ash content ≤8% through COA.

• Batch Stability: Request the supplier to provide test reports for 3 consecutive batches and compare the fluctuation range of viscosity and DS (fluctuation should be ≤5%) — excessive batch differences can lead to unstable product texture (e.g., sauces becoming thin or thick alternately) and increase production risks.

• Impurity Control: Focus on residual solvents (e.g., ethanol), heavy metals, and microbial indicators — food grade requires zero pathogenic microorganisms, while pharmaceutical grade requires additional control of endotoxin content to avoid product deterioration or safety risks.

Part 5: Why Source CMC-Na From Us?

As a supplier specializing in natural polymer derivatives and functional raw materials, Hangzhou Greensky Biological Tech. Co., Ltd has core competitiveness in the production and service of CMC-Na:

• Full-Link Quality Control: From "high-purity cotton linter raw material screening" to "precision control of etherification process" and "multi-stage purification of finished products", each link adopts automated equipment and standardized SOPs, ensuring product DS fluctuation ≤3%, viscosity fluctuation ≤5%, purity ≥99.5%, and full compliance with strict food-grade and pharmaceutical-grade standards.

• Full Specification Coverage and Customization: We provide a full range of CMC-Na products with DS 0.6-1.2 and viscosity 50-10000 mPa·s, while supporting customized needs — e.g., developing low-sodium CMC-Na for low-salt foods, providing USP-NF grade low-endotoxin products for pharmaceutical customers, and offering 50g-1kg sample testing services.

• Full Compliance Certification System: The products have passed GB 1886.232 and pharmaceutical-grade products comply with USP-NF and EP standards. We can provide complete certification documents, traceability reports, and COA to ensure customers pass downstream regulatory audits smoothly.

• Stable Supply and Technical Support: we can support rapid delivery of orders from 10kg to 100 tons. Our professional technical team can provide "formulation adaptation guidance" (e.g., recommending optimal addition levels) and "problem-solving solutions" (e.g., resolving system stratification issues) to help customers develop products efficiently.

Conclusion and Call to Action

With its core advantages of "natural safety, comprehensive functions, and wide adaptability", Sodium Carboxymethyl Cellulose (CMC-Na) has become a key link connecting natural raw materials and modern industry — whether the food industry pursues "balance between taste and shelf life", the pharmaceutical industry focuses on "compliance and safety", or the industrial sector requires "efficiency and stability", high-quality CMC-Na can provide precise solutions.

If you are interested in CMC-Na products or need to customize parameters for specific application scenarios (e.g., low-viscosity salt-tolerant type, high-viscosity water-retention type), please contact us today to request the latest quotation and free sample. Our expert team will provide one-stop services of "parameter selection + addition level testing + process adaptation" based on your formulation needs to help you upgrade your products and expand your market.

- ▶ Hesperidin

- ▶ citrus bioflavonoids

- ▶ plant extract

- ▶ lycopene

- ▶ diosmin

- ▶ grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ beetroot powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ reishi mushroom extract

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin Extract

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol Extract

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ blog3

- ▶ blog4

- ▶ blog5

- ▶ Red Yeast Rice

- ▶ Red Wine Extract