- 0086-571-85302990

- sales@greenskybio.com

Preparation process of lemon extract.

2024-12-10

1. Introduction

Lemon Extract is a valuable substance with a wide range of applications in the food, beverage, cosmetic, and pharmaceutical industries. It is rich in various bioactive compounds such as citric acid, flavonoids, and essential oils, which contribute to its unique flavor, antioxidant, and antibacterial properties. The preparation process of Lemon Extract is crucial to ensure its quality, yield, and purity. In this article, we will explore the detailed steps involved in the preparation of Lemon Extract, from the selection of raw materials to the final purification and concentration steps.

2. Selection and Collection of Lemons

The quality of lemons is the foundation of high - quality lemon extract. When selecting lemons, several factors need to be considered:

- Maturity: Ripe lemons are preferred as they contain a higher concentration of bioactive compounds. Lemons that are too green may lack the full flavor and nutritional content, while overripe lemons may have started to decay or lose some of their valuable components.

- Appearance: Lemons should have a smooth, unblemished skin. Avoid lemons with bruises, cuts, or signs of mold as these can introduce contaminants into the extract.

- Size: Although size does not directly correlate with the quality of the extract, larger lemons may be more convenient for processing and may yield a relatively larger amount of extract.

Once the suitable lemons are selected, they need to be carefully collected. This process should be carried out gently to avoid damaging the lemons. Lemons can be hand - picked from the trees or harvested using appropriate mechanical devices in large - scale production.

3. Cleaning and Preparation of Lemons

Before extraction, lemons must be thoroughly cleaned to remove any dirt, pesticides, and other contaminants. The cleaning process typically involves the following steps:

- Rinsing: Lemons are rinsed under running water for a sufficient period to wash away loose dirt and debris.

- Soaking: After rinsing, lemons may be soaked in a mild solution of food - grade detergent or a diluted vinegar solution for a short time. This helps to remove more stubborn contaminants such as pesticides residues. However, it is important to rinse the lemons thoroughly again after soaking to ensure that no detergent or vinegar remains.

After cleaning, the lemons need to be prepared for extraction. This may involve cutting the lemons into appropriate pieces. For example, they can be halved or quartered depending on the extraction method to be used. Some extraction processes may require the removal of the peel, while others can utilize the whole lemon including the peel.

4. Mechanical Pressing and Extraction

Mechanical pressing is a common method for extracting juice from lemons, which is the first step in obtaining lemon extract. There are different types of mechanical presses available:

- Hydraulic Press: This type of press applies a large amount of force using hydraulic pressure. Lemons are placed in a press chamber, and the pressure is gradually increased until the juice is squeezed out. Hydraulic presses are known for their high - pressure capabilities and can extract a relatively large amount of juice from lemons. However, they are also relatively expensive and require more maintenance.

- Screw Press: Screw presses work by using a rotating screw to gradually squeeze the lemons. The lemons are fed into one end of the screw, and as the screw rotates, the juice is forced out through a screen or perforated plate. Screw presses are more commonly used in small - to medium - scale operations as they are relatively simple and cost - effective.

Once the juice is obtained through mechanical pressing, further extraction techniques may be employed to isolate the desired components from the juice. One such technique is solvent extraction.

Solvent extraction involves using a suitable solvent to dissolve the target compounds in the lemon juice. Commonly used solvents include ethanol and ethyl acetate. The solvent is added to the lemon juice, and the mixture is stirred thoroughly to ensure good contact between the solvent and the juice. After a certain period of extraction time, the mixture is separated into two phases: the solvent phase containing the dissolved compounds and the aqueous phase (the remaining lemon juice). The solvent phase is then collected for further processing.

5. Modern Technologies for Improving Yield and Purity

In recent years, several modern technologies have been developed to improve the yield and purity of lemon extract:

- Ultrasonic - Assisted Extraction: Ultrasonic waves are applied during the extraction process. The ultrasonic vibrations create cavitation bubbles in the extraction medium, which helps to break down the cell walls of the lemon tissues more effectively. This results in a higher release of bioactive compounds into the extraction solvent, thereby increasing the yield of the extract. Additionally, ultrasonic - assisted extraction can reduce the extraction time compared to traditional methods.

- Supercritical Fluid Extraction: Supercritical fluids, such as supercritical carbon dioxide (scCO₂), are used as extraction solvents. Supercritical fluids have properties between those of a liquid and a gas, which allows for better penetration into the lemon matrix and selective extraction of specific compounds. This method can produce a highly pure extract with a relatively high yield. Moreover, scCO₂ is non - toxic, non - flammable, and environmentally friendly, making it an attractive option for lemon extract production.

- Membrane Filtration: Membrane filtration techniques can be used to separate and purify the lemon extract. Different types of membranes with specific pore sizes can be employed to remove impurities such as proteins, polysaccharides, and large - molecular - weight compounds while retaining the desired bioactive components. This helps to improve the purity of the extract and can also be used in the concentration step.

6. Purification and Concentration

After the initial extraction, the lemon extract often contains impurities and needs to be purified and concentrated to meet the requirements for different applications.

Evaporation is a common method for concentration. The lemon extract is heated gently under reduced pressure to evaporate the solvent (if a solvent was used in the extraction) and some of the water content. This process increases the concentration of the bioactive compounds in the extract. However, care must be taken to avoid over - heating, which can cause degradation of the compounds.

Column Chromatography can be used for purification. The lemon extract is passed through a chromatography column filled with a suitable stationary phase (such as silica gel or a resin). Different compounds in the extract interact differently with the stationary phase, and they are eluted at different times. This allows for the separation and removal of impurities, resulting in a purer lemon extract.

Another purification method is crystallization. In some cases, certain components in the lemon extract can be crystallized out by adjusting the temperature, pH, or concentration conditions. The crystallized impurities can be removed, leaving behind a more purified extract.

7. Quality Control and Packaging

Quality control is an essential part of the lemon extract preparation process. The following parameters are typically monitored:

- Chemical Composition: The concentration of key bioactive compounds such as citric acid, flavonoids, and essential oils is analyzed using appropriate analytical techniques such as high - performance liquid chromatography (HPLC) or gas chromatography - mass spectrometry (GC - MS).

- Purity: The presence of impurities such as heavy metals, pesticides residues, and microbial contaminants is tested.

- Physical Properties: Parameters such as color, odor, and viscosity are also evaluated.

Once the lemon extract passes the quality control tests, it is ready for packaging. The packaging material should be chosen based on the stability and shelf - life requirements of the extract. For example, amber - colored glass bottles are often used to protect the extract from light - induced degradation. The packaging should also be airtight to prevent oxidation and contamination.

8. Conclusion

The preparation process of lemon extract involves multiple steps from the selection of lemons to the final packaging. Each step is crucial in determining the quality, yield, and purity of the extract. With the development of modern technologies, it is possible to improve the efficiency and quality of lemon extract production. However, strict quality control measures must be implemented throughout the process to ensure that the lemon extract meets the high standards required for various applications in the food, beverage, cosmetic, and pharmaceutical industries.

FAQ:

What are the key factors in selecting fresh lemons for lemon extract preparation?

When selecting fresh lemons for lemon extract preparation, several key factors should be considered. Firstly, the ripeness of the lemons is crucial. Ripe lemons tend to have a higher concentration of the desired compounds, such as citric acid and essential oils. Secondly, the quality and freshness of the lemons matter. Lemons free from blemishes, mold, or signs of decay are preferred as they are more likely to yield a pure and high - quality extract. Additionally, the origin of the lemons can also play a role. Lemons from certain regions may have different flavor profiles or chemical compositions due to variations in soil, climate, and cultivation methods.

What mechanical pressing methods are commonly used in lemon extract preparation?

There are several mechanical pressing methods commonly used in lemon extract preparation. One of the most basic methods is manual pressing using a citrus press. This simple device allows for the extraction of juice from the lemon by applying pressure. Another method is hydraulic pressing, which uses hydraulic pressure to squeeze out the juice and other extractable components from the lemon pulp. Centrifugal extraction is also a popular method. In this process, the lemons are first crushed, and then the resulting mixture is spun in a centrifuge. The centrifugal force separates the liquid extract from the solid parts of the lemon.

How do modern technologies enhance the yield of lemon extract?

Modern technologies enhance the yield of lemon extract in multiple ways. For example, advanced extraction techniques such as supercritical fluid extraction (SFE) can be used. SFE uses a supercritical fluid, usually carbon dioxide, which has properties between a gas and a liquid. It can penetrate the lemon cells more effectively and extract a greater amount of the desired compounds compared to traditional methods. Another technology is microwave - assisted extraction. Microwave energy can break down the cell walls of the lemon more efficiently, allowing for better release of the extractable components. Additionally, enzymatic treatment can be applied. Enzymes can hydrolyze the cell wall polysaccharides, making it easier to extract the juice and other valuable substances from the lemons.

What is the importance of purification in the preparation of lemon extract?

Purification is of great importance in the preparation of lemon extract. Firstly, it helps to remove impurities such as pulp residues, waxes, and other unwanted substances that may be present in the initial extract. This ensures that the final product has a clean and pure taste. Secondly, purification can separate out any potential contaminants or harmful substances. For example, pesticides or heavy metals that might be present on the lemon skins can be removed during the purification process. Moreover, purification can also help in concentrating the desired active components in the extract, such as citric acid and essential oils, which is important for its effectiveness in various applications.

How is the concentration of lemon extract typically carried out?

The concentration of lemon extract is typically carried out through evaporation methods. One common approach is thermal evaporation, where the extract is heated under controlled conditions to evaporate the water content, thereby increasing the concentration of the desired components. Another method is vacuum evaporation, which is carried out under reduced pressure. This helps to lower the boiling point of the liquid in the extract, allowing for more efficient evaporation at lower temperatures. This is beneficial as it can prevent the degradation of heat - sensitive components in the lemon extract.

Related literature

- Optimization of Lemon Extract Preparation Using Novel Extraction Technologies"

- "Purification and Concentration Processes in Lemon Extract Production"

- "The Role of Fresh Lemon Selection in High - Quality Lemon Extract Preparation"

- ▶ Hesperidin

- ▶ Citrus Bioflavonoids

- ▶ Plant Extract

- ▶ lycopene

- ▶ Diosmin

- ▶ Grape seed extract

- ▶ Sea buckthorn Juice Powder

- ▶ Fruit Juice Powder

- ▶ Hops Extract

- ▶ Artichoke Extract

- ▶ Mushroom extract

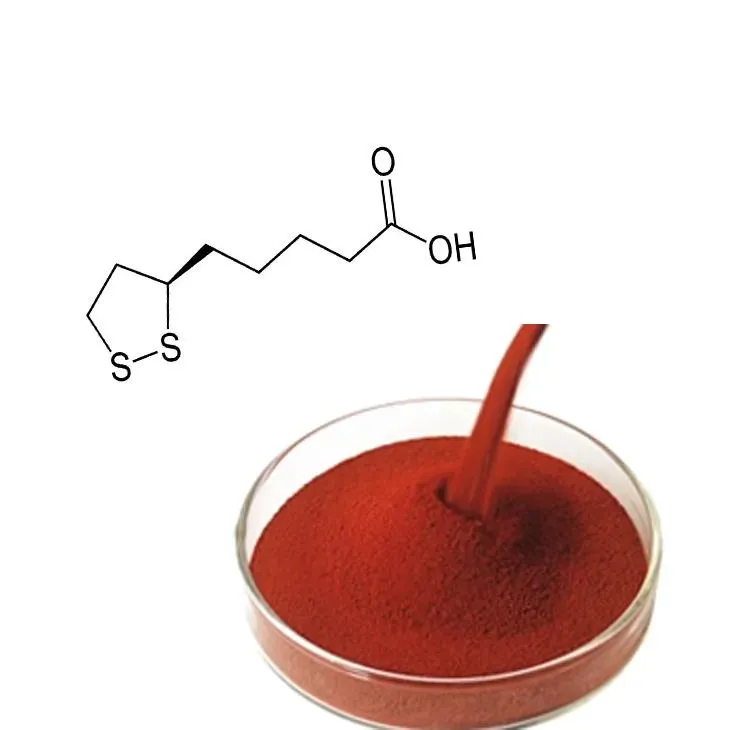

- ▶ Astaxanthin

- ▶ Green Tea Extract

- ▶ Curcumin

- ▶ Horse Chestnut Extract

- ▶ Other Product

- ▶ Boswellia Serrata Extract

- ▶ Resveratrol

- ▶ Marigold Extract

- ▶ Grape Leaf Extract

- ▶ New Product

- ▶ Aminolevulinic acid

- ▶ Cranberry Extract

- ▶ Red Yeast Rice

- ▶ Red Wine Extract

-

Purple Sweet Potato Extract

2024-12-10

-

Astaxanthin

2024-12-10

-

Sea buckthorn Juice Powder

2024-12-10

-

Lily extract

2024-12-10

-

Green coffee bean Extract

2024-12-10

-

Bayberry Extract

2024-12-10

-

Milk Thistle Extract

2024-12-10

-

Tongkat Ali Extract

2024-12-10

-

Camu Camu Extract

2024-12-10

-

Pomegranate Extract

2024-12-10